According to the notification from Wujin District Emergency Management Bureau, Changzhou, Jiangsu Province

At 3: 38 on January 20th.

A dust explosion occurred in the workshop of Changzhou Shenrong Metal Technology Co., Ltd., located in Nanxiashu Street, Wujin District.

A total of 8 people were killed and 8 were slightly injured.

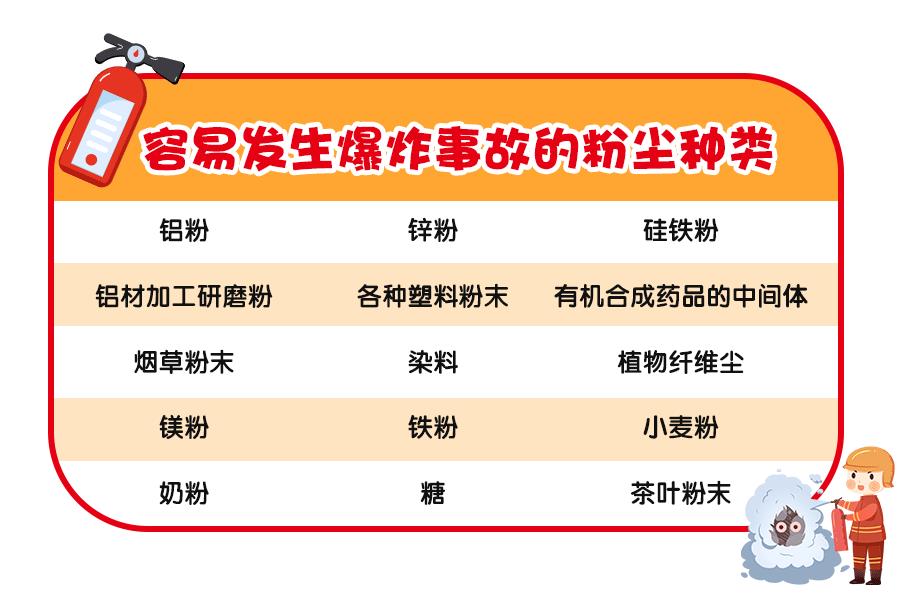

Safety tips for dust explosion

Dust explosion is caused by combustible dust.

Encounter a heat source within the explosion limit.

(open flame or high temperature)

Dust explosion is extremely harmful.

It often causes heavy casualties.

Five elements of dust explosion

Combustion-supporting gas: A certain oxygen content is the basis of dust combustion.

Combustible dust: dust that can be oxidized and burned with combustion-supporting gas.

Ignition source: a high-temperature heat source that can make the temperature of local dust clouds suddenly increase and burn.

Dust cloud: combustible dust cloud suspended in the air and reaching the lower explosion limit.

Confined space: the dust cloud is confined in a relatively closed space.

Characteristics of dust explosion

Multiple explosions are the biggest feature of dust explosion.

When air billow explodes for the first time, it will blow up the dust deposited on the equipment or the ground. In a short time after the explosion, negative pressure will be formed in the center of the explosion, and the surrounding fresh air will be filled in from the outside to mix with the raised dust, thus triggering a second explosion. During the second explosion, the dust concentration will be higher.

Safety management of enterprises involved in dust explosion

Relevant regulations

Which enterprises are involved in dust explosion?

"Safety Regulations on Dust Explosion in Industry and Trade Enterprises" Article 2 These Provisions shall apply to the dust explosion safety work and supervision and management of metallurgical, nonferrous metals, building materials, machinery, light industry, textiles, tobacco, commerce and other industry and trade enterprises (hereinafter referred to as dust explosion-related enterprises) which are in danger of combustible dust explosion.

What should be included in the enterprise dust explosion-proof safety management system?

Article 7 A dust explosion-related enterprise shall establish and implement a dust explosion-proof safety management system according to the actual situation of the enterprise. The dust explosion-proof safety management system shall include the following contents:

(1) Risk identification, assessment and control of dust explosion;

(two) the investigation and management of hidden dangers of dust explosion accidents;

(3) Safety operation procedures for dust jobs;

(4) Education and training on special safety production for dust explosion prevention;

(5) Dust cleaning and disposal;

(6) Operation, maintenance, overhaul and maintenance management of dust removal system and related safety facilities and equipment;

(seven) emergency treatment and rescue of dust explosion accidents.

Dust-related explosion enterprises

Criterion for judging major hidden dangers

What are the circumstances of related enterprises that have been judged as major accidents?

"Criteria for Judging Major Accident Hidden Dangers of Industrial and Commercial Enterprises" Article 11 An industrial and commercial enterprise with the risk of dust explosion shall be judged as a major accident hidden danger in any of the following circumstances:

(1) The hazardous place for dust explosion is set in a multi-storey building (structure) with non-frame structure, or there are places for gathering staff such as dormitory, conference room, office and lounge in the hazardous place for dust explosion;

(2) Different types of combustible dust, combustible dust, combustible gas and other media that are likely to aggravate the explosion risk share a dust removal system, or different buildings (structures) and different fire zones share a dust removal system and the dust removal systems are interconnected;

(three) the dry dust removal system did not take any explosion prevention and control measures such as explosion venting, inerting and explosion suppression;

(4) When the dust removal system of metal dust such as aluminum and magnesium adopts positive pressure dust removal, or other combustible dust removal systems adopt positive pressure dust blowing, measures such as spark detection and elimination are not taken to prevent ignition sources;

(five) the dust removal system adopts gravity settling chamber for dust removal, or adopts dry roadway structure as dust removal air duct;

(six) the dry dust removal system of aluminum, magnesium and other metal dust and wood dust is not equipped with a gas lock and ash discharge device;

(seven) the electrical equipment in the dust explosion dangerous places divided into 20 zones, such as dust collectors and dust collection bins, does not meet the explosion-proof requirements;

(eight) before crushing, grinding, granulating and other process equipment that are easy to generate mechanical ignition sources, there is no iron, stone and other sundries removal device, or the air duct connected with the sander in the wood processing enterprise is not equipped with a spark detection and elimination device;

(9) Failing to take ventilation and other measures to prevent hydrogen accumulation in the collection, stacking and storage places of spontaneous combustion metal dust when wet, or failing to take waterproof and moisture-proof measures in the dry collection, stacking and storage places;

(ten) did not implement the dust cleaning system, resulting in serious dust on the job site.

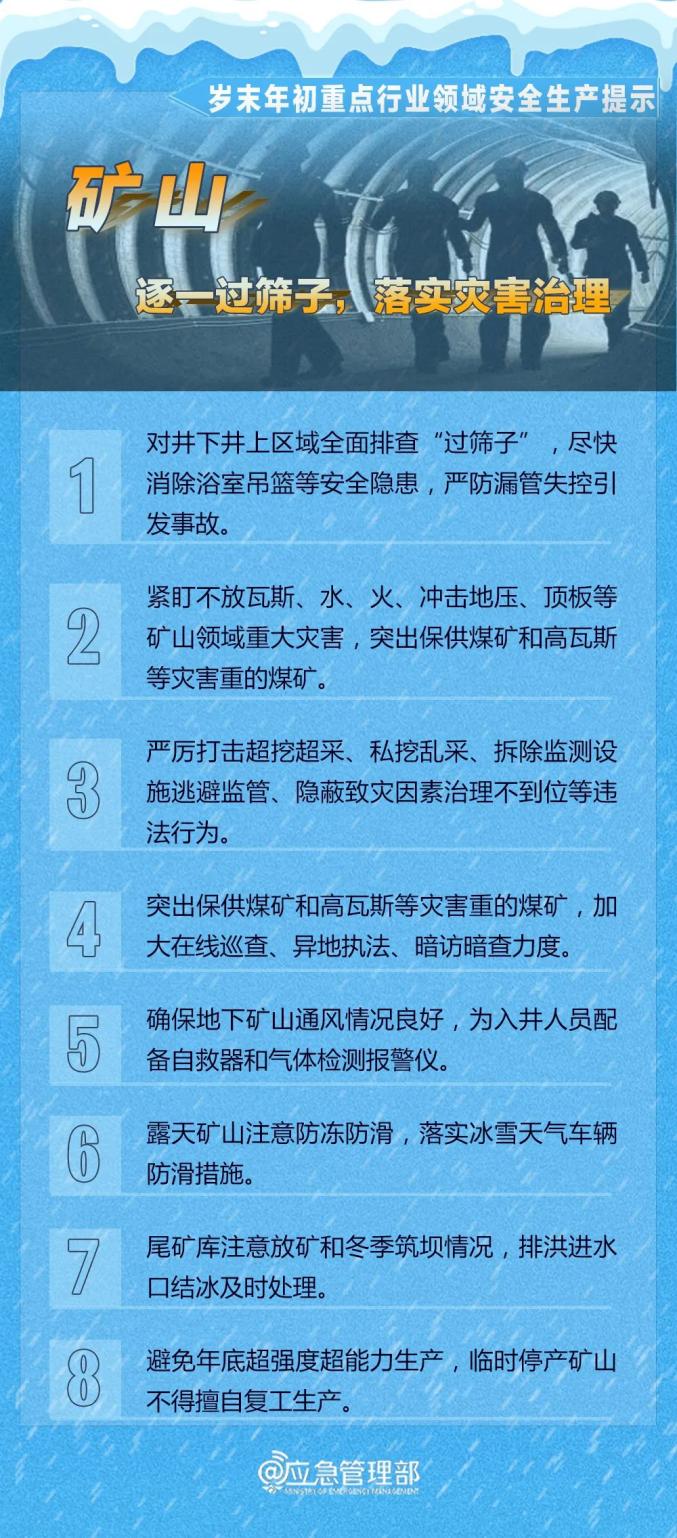

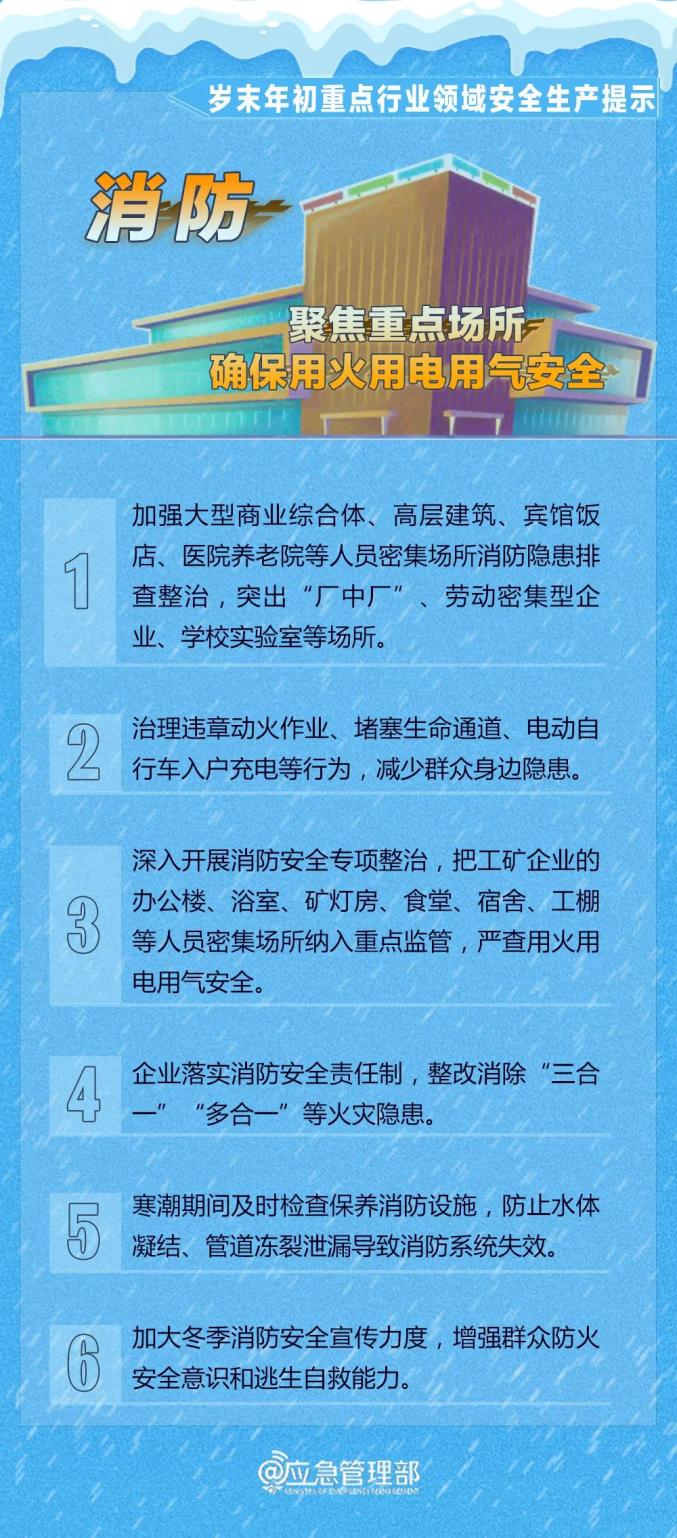

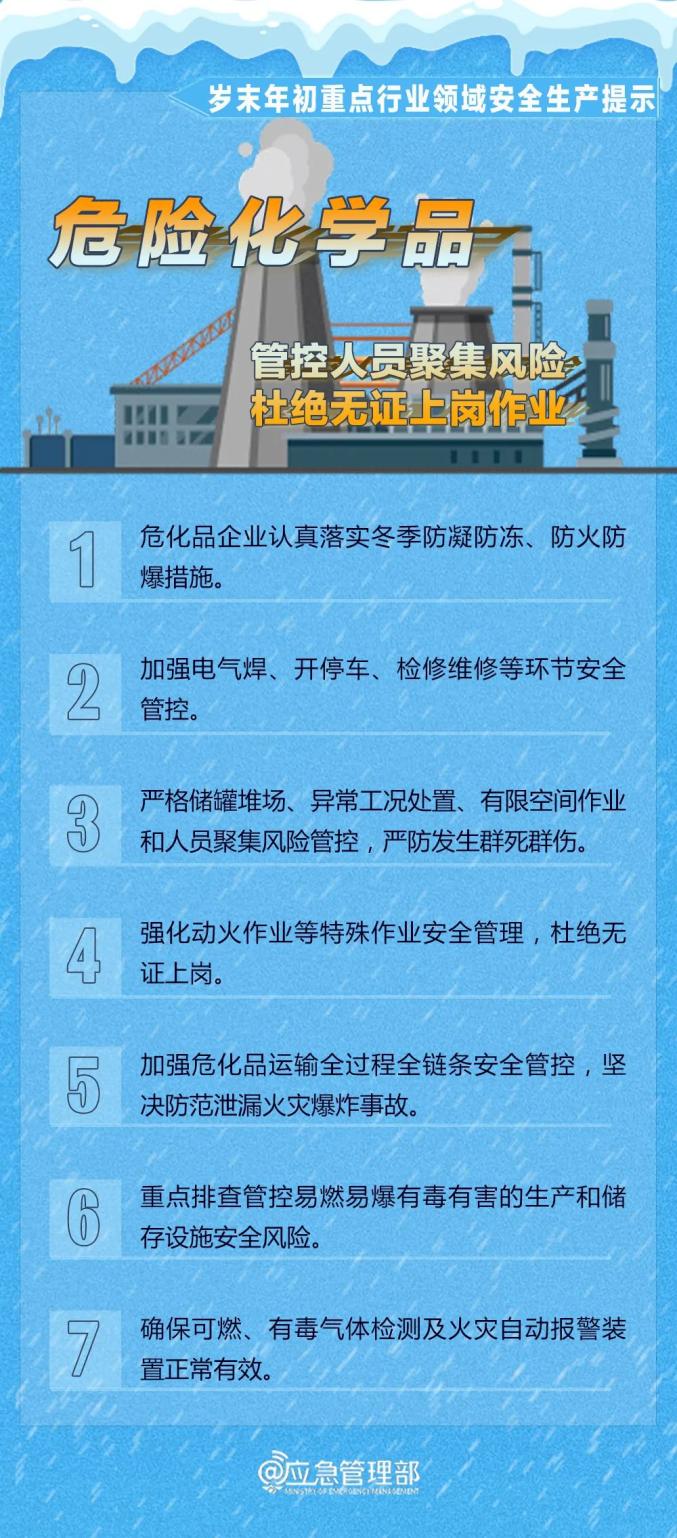

It’s the end of the year and the beginning of the year.

Industry and trade, mining, fire protection and other key industries.

This safety production tip

Please put it away!

Original title: "Dust explosion, 8 deaths and 8 injuries! Urgent reminder! 》

Read the original text