Mention gutter oil

Many people’s first reaction is harmful to health.

But if you use it in the right place,

Waste oil can also play its value.

recent days

An A350 aircraft was accepted by Air China.

The plane used 5% sustainable fuel for its first flight.

Its raw material is waste oil.

Adopt technology with independent intellectual property rights for production.

The big plane drank "gutter oil"

Not only can you sail normally

It can also achieve green flight.

The aviation industry has made a key breakthrough in emission reduction.

Let "gutter oil" fly to the sky.

It is by China Petrochemical Research Institute.

The first bio-jet fuel industrial device developed in China

The device is made of used cooking oil and edible oil.

That is, waste oil

Production of bio-jet fuel as raw material

(Bio-jet fuel:

It is aviation kerosene produced with renewable resources as raw materials.

Raw materials mainly include waste cooking oil,

Animal and vegetable oils, agricultural and forestry wastes, etc.)

Compare with that traditional petroleum-based aviation kerosene

Carbon Dioxide Emission of Bio-jet Fuel in Life Cycle

The maximum emission reduction can be more than 50%

The device can "swallow" about 100,000 tons of "gutter oil" every year.

Spit out 40,000 to 50,000 tons of clear biological aviation kerosene.

Converted, it can reduce carbon dioxide emissions by about 80 thousand tons per year.

It is equivalent to nearly 50,000 economical cars being shut down for one year.

"Waste oil" turns waste into treasure

The biggest difficulty is that

Waste oil contains a lot of fatty acid compounds.

Its oxygen content is as high as 11%

And traditional raw materials—

The oxygen content of petroleum is less than 0.1%

The difference is more than 100 times

Direct influence of oxygen molecules

Activity and stability of catalyst in refining and chemical plant

In addition, gutter oil also contains

Sulfur, chlorine, metal elements and other impurities.

Have to be removed one by one.

Bio-oil raw materials which can be used to produce bio-aviation kerosene. Source: China Petrochemical Research Institute

To this end, China Petrochemical independently developed

Special catalyst and process

And has been demonstrate and verified by an industrial scale device.

May this year

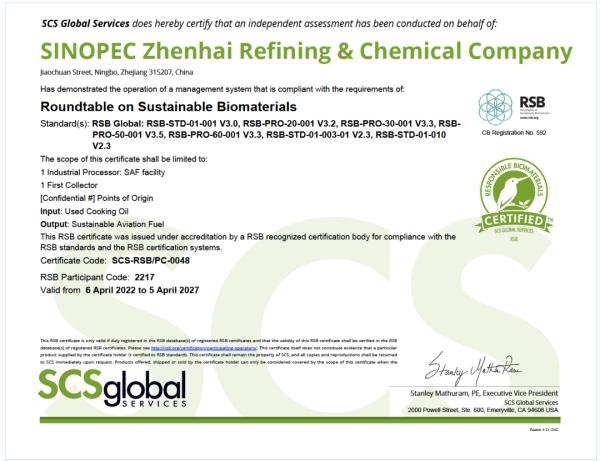

HEFA route of Zhenhai Refining and Chemical Company

Biological aviation fuel products pass

RSB certification for sustainable biomaterials

This certification

It is obtained from China’s biological aviation coal products.

The first global sustainability certification.

It shows that Zhenhai Refining & Chemical Biological Aviation Coal Device

Raw materials, production technology and products are all in line with.

Basic principles and standards of sustainable development of RSB biofuels

According to calculation

A city of ten million people.

The actual recovery of waste oil after meals is about 10,000 tons per month.

Recover more than 100,000 tons of waste oil every year.

Considering the conversion of waste oil yield

If the device is operated at full load

It can be basically digested in one year.

Waste oil recovered from a city with a population of 10 million.

Some netizens said:

"This is technology and hard work!"

I didn’t expect it.

The gutter oil that everyone "abandoned" one day

Can be turned into high-value fuel.

This is the proper way to turn waste into treasure.

Transferred from: CCTV Comprehensive @ Xiaoyang Video, China Petrochemical, The Paper

]