This morning, the meteorological observatory of Tonglu County in Hangzhou issued a rainstorm red warning signal, and some township streets have experienced short-term heavy precipitation of more than 100 mm. Serious water accumulation occurred in some sections of the urban area. Some township roads were broken by flash floods, farmland was flooded, and some farmhouses were flooded. Tonglu County has launched a level 2 emergency response to flood control, and all relevant departments have urgently carried out rescue and relief work. Zhejiang video reporters broadcast the rescue progress live.

Time: June 19, 2019, 15:00-17:00

标签: 上海后花园

I swear at least 100 words, just to finish this film.

(WeChat ID: dushetv)

Chinese new year is coming, I don’t want to work, I just want to fish.

As it happens, there is something breaking this week.

Look at the title, it’s swearing.

After reading it, you should call Wocao-

No excitement?

[bloody hell]

Bloody Hell

Bloody hell?

Just look at English bloody hell. It’s a dirty word.

Pun intended.

Just like this movie, there are horror, comedy and indescribable madness.

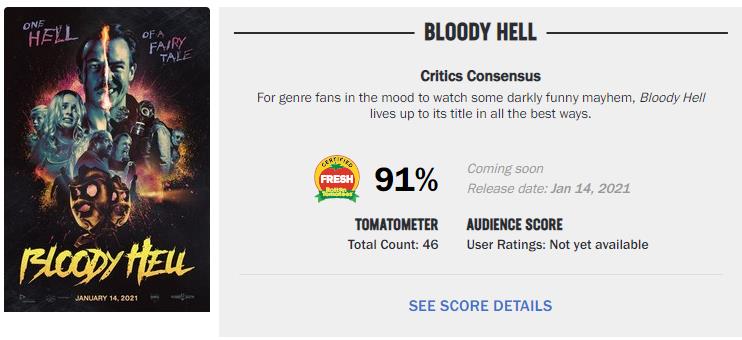

The freshness of rotten tomatoes is 91%, and watercress is 7.1.

This score belongs to a horror film.Must see.

The story begins with the fucking life of the protagonist.

On an ordinary day, the hero Rex made eyes at the bank and the counter girl.

Unless something goes wrong, Rex can have a sweet date today.

However, the accident is coming.

A gang of gunmen broke into houses.

Killed a security guard without saying anything.

Boody hell! (Damn it! )

Looks like the robbers didn’t just take the money.

And take away the love that Rex is about to get.

What else can I do? I can only live.

But then fate gave him a second one.bloody hell——

Pa, a bag with a gun in it fell in front of Rex.

So rex’s protagonist possessed the aura.

Pulling out a gun is killing all sides and saving the hostages.

Became a hero?

andbloody hell!

What awaits him is not honor, but prosecution-

Because of excessive defense, unnecessary casualties were caused.

Rex ended up in prison for eight years.

What’s this called?

If it were you, would you hate it or not?

After he got out of prison, he was recognized walking in the street and was still bullied.

The whole society, only tm is an unreasonable prison.

Rex decided to get the hell out of here.

Where to?

He uses biu~ to decide

Look, Finland-

Without a word, pack your things and set off immediately.

But one of the great laws of horror movies is-

No matter how you run away, things will always go wrong.

Bloody hell is like a shadow. Wherever he goes, he follows …

Looks like a horror movie.

But what you see is clearly a social animal that has been repeatedly hit and trampled into the mud by life. (Sounds like it’s even scarier.)

When you are deprived of something a little bit.

Before which bottom line will you fight with your life?

Get on the black car.

Imprisoned in a warehouse.

Found a leg missing.

Want to shout, but suddenly a hand over your mouth …

Now recognize it clearly.

Bad things will not let Rex go.

He escaped from a bloody hell and fell into another fire pit-

pairOgre couple.

But here comes the problem.

Even if you really want to resist.

In a strange foreign country, I broke my leg and was firmly tied.

How to escape?

Sir, there are not many spoilers.

Anyway,I won’t let you guess.

For example, when the man is ready to untie the rope with his mouth.

Only to find that without legs, I lost a lot of weight, and I didn’t even breathe when I did 10 pull-ups …

Ok! Open! Heart!

Another example is.

The daughter of a cannibal family sneaked in in the middle of the night. Did she find out his escape plan, or did she want to steal a supper while her family was asleep?

All wrong!

As a result, she was in love and decided to elope with the man.

The opening of a heavy-mouthed horror film.

It can develop a romantic story that a knight meets a princess, defeats a monster (her family) and gains love.

There are quite a few crazy scenes in the movie.

Fan stalks pop up from time to time.

There are bicycles in the warehouse.

Rex began to brainstorm the beautiful scene of the family riding bicycles together in the countryside.

It is also intimately accompanied by Finland’s iconic onion song.

The blackest humorous scene is.

When the man is fighting.

Accidentally opened the refrigerator door-

What’s inside is the foot that you haven’t eaten yet.

(Pretending to have a picture)

How would you feel if it were you?

The next scene in the movie reveals his inner activities-

Finally reunited with my little jiojio.

And this foot he lost.

It also became the key to finally saving his life.

Nerve and plasma.

It’s two legs dancing happily in bloody hell.

But what is this dance that no one knows?

You see, in many scenes, it exists."two men"——

One is Rex.

One is the other self in his heart.

Where did this split personality come from?

Rex’s words gave a hint-

Remember?

In Afghanistan

These two faces represent his confusion between justice and killing.

Take Afghanistan as the key.

You can read many secret codes in the movie.

For example, in a bank.

Rex was encouraged by his inner self.

Is there a boundary for the killing of "gangsters"?

Who should be responsible for those civilians who were hurt in the war?

Rex retaliated by shooting the gangster’s penis for killing his red eye, resulting in a lady being shot and killed.

But he has already forgiven himself in his heart.

And rationalize their own killings.

Bloody hell is nothing else.

It is the unreasonable logic of war.

Whether a hero or a pervert depends on whether Rex admits his divided self.

And the direction of the story is emphasized to Rex again and again.

Being a hero can save others.

Being a pervert can save yourself.

In the end, Rex’s choice may have no suspense.

Once in hell, it’s hard to wear away the mark, let alone be born in hell.

The picture in this article comes from the Internet.

Editor’s assistant: super rich mother-in-law

Fan interaction

What do you think of [bloody hell]?

Share your viewing experience with more fans.

The eyebrow tattoo experience of 25-year-old white-collar workers in Yang Mei: The service is professional and intimate, and it is hard to make people not love it!

In this era of beauty-loving, every girl hopes that her face value can be improved higher, among which eyebrows play an important role in the temperament of the five senses.

Recently, after eyebrow tattooing, many sisters have been asking me: Is eyebrow tattooing good? Will it be tattooed? How long can tattooed eyebrows last? Today, I will share with you my experience in eyebrow tattooing, hoping to help you.

Although many people now say that tattooing eyebrows is easy to step on thunder, what I want to say is that this is related to technology, eyebrow tattooing products and the level of eyebrow tattooers.

Before tattooing eyebrows, I searched the Internet to learn about all kinds of tattooed eyebrows, and after comparing with different tattooed eyebrow shops, I finally chose Yang Mei tattooed eyebrows, because their design styles are in line with what I want, and the prices are very reasonable. After tattooing your eyebrows, you can finally get rid of the trouble of going out to thrush every day.

Under the communication design with the eyebrow tattoo artist, I chose the wild eyebrow. When designing the eyebrow shape, the teacher carefully helped me analyze the face characteristics and customize the eyebrows according to the face shape.

The technique of eyebrow tattooing is very important. If the technique is not up to standard, the effect of tattooing will be unsatisfactory. All eyebrow tattooers have qualified tattoo artist qualification certificates, and their operating experience is more than 5 years.

The material of eyebrow tattoo is also very important. Inferior materials may cause skin allergies, fade into blue eyebrows and red eyebrows in the later stage, and pure plant dyes are used for the eyebrows, which can perfectly guarantee the later effect of customers.

The decoration style of Yangmei Store is simple and advanced, and the supplies are all changed by one customer. There is no tingling and discomfort during the operation, and there is no price for selling products during the operation. The operation process is between one and two hours.

The final effect after eyebrow tattooing is the same as the eyebrow shape when it is designed. The wild eyebrows have distinct roots and the flu is bursting, just like their own growth.

The eyebrow shape can be maintained for 3-5 years, and it can be repaired again for free in case of color fading. After the eyebrow tattoo, the teacher will also send drinks, fruits and later care products intimately, and remind you of the precautions after eyebrow tattoo.

Finally, I really like the eyebrow shape designed. The attitude of the eyebrow tattoo artist is really very good, and the follow-up guarantee is also in place. The whole eyebrow tattoo process is very pleasant.

After tattooing eyebrows, it really saves time and can become beautiful. Sisters are also crazy after seeing it. No wonder Yang Mei can stand out from so many tattoo shops!

Give full play to the multi-subject strength

"Six Clean-ups" Work Law Helps Community Safety Without "Epidemic"

There are 4 communities in Qingyou Xili Community, Nanshi Street, Heping District, Tianjin, with 1,461 households and 4,231 people. The old and new communities in the area are mixed together, and the population mobility is large. Facing the severe situation of epidemic prevention and control, Wang Jinrong, secretary of the community Party Committee, actively explored and formed the "six clean-ups" work method to help the community to be safe from "epidemic".

Pingyang Road No.2 Community, Yingpan Sub-district Office, xiaodian district, Taiyuan City, Shanxi Province, has done a good job in registering visitors and persuading them to return.

According to reports, the "six clean-ups" means that the contents of prevention and control propaganda in COVID-19 are clear, the classification accounts are clear, the follow-up key personnel are clear, the follow-up visits are clear, the service key projects are clear, and the responsibilities of the four departments (streets, communities, hospitals and police stations) are clear, so as to resolutely ensure that "no one is left behind" and provide accurate real-time dynamic data for district and street disease prevention and control departments.

Since the outbreak, Qingyou Xili community has actively carried out joint prevention and control work under the leadership of the community party Committee. All community workers returned to their posts at the first time, and a strong joint defense and control team was formed by street leaders, community grid members, cadres of sinking organs, on-the-job party member, volunteers and security personnel of property service enterprises to strengthen community management.

At the beginning of the outbreak, Qingyou Xili community vigorously publicized the community residents at the first time, and implemented the grid management requirements, and arranged the community personnel to ensure that "no one was left behind", focusing on the registration of those returning from other places, especially Wuhan, and establishing a ledger. Under the principle of meeting the normal travel needs of residents, temporarily adjust and close some entrances and exits, and take measures such as disinfection, registration of entry and exit personnel, temperature measurement, issuance of community passes, and scanning of the two-dimensional code of "Jinmen War and Epidemic" for closed management. In residential areas with property services, the gate and access control system should be strictly observed, and measures such as real-name registration of residents entering the residential area, monitoring the body temperature of people entering and leaving the residential area, reducing unnecessary personnel flow and persuading people to gather in the residential area should be taken to strengthen the linkage between the community and property service enterprises, and joint prevention and control of epidemic situation should be carried out.

Community workers also work with the staff of the property service enterprises to carry out sanitary cleaning work in the community, and clean, disinfect and ventilate the closed spaces such as garbage cans, public places and elevators in the community every day. The community gave the donated masks to the residents in difficulty, and provided masks, disinfectant, fruits and other materials for the security personnel of the property service enterprises, which greatly eased the pressure on the property service enterprises and enabled the property service personnel to work with peace of mind.

In the later period of epidemic prevention and control, party member, the old community manager, and so on also participated in the epidemic prevention work. They not only helped the community to carry out personnel arrangement, but also cooperated with the staff of the property service enterprise to carry out health monitoring and tracking management for the migrants.

Among these people, Wang Jinrong is the busiest. Her figure can be seen everywhere, running the community and running the stairs during the day, and getting familiar with the situation and sorting out data in the office at night until one or two in the morning. And no matter how late you worked overtime the day before, at 8 o’clock the next morning, Wang Jinrong will definitely come to Tianjin and return to Tianjin to check the registration status on time. She often doesn’t care about eating a hot meal, but she always thinks about whether the elderly living alone and empty nesters in the community eat safely and comfortably. In Qingyou Xili community, people over 70 years old account for more than 40%. During the epidemic prevention and control period, the dining hall for the elderly in the community stopped eating and delivering food, but some elderly people who live alone and have mobility difficulties still have demand. Wang Jinrong went door-to-door to record the demand, and distributed community grid workers and volunteers according to the principle of proximity to provide catering services for the elderly. In just one day, the community "good neighbor kitchen" was officially employed. In order to ensure the safety and hygiene of meals for the elderly, Wang Jinrong takes the temperature of volunteers who deliver food every day, asking them to wear disposable masks and gloves, clean lunch boxes and disinfect them. Every time a meal is delivered, Wang Jinrong will immediately take out the alcohol cotton ball he carries with him and carefully wipe his hands, and then take out the next meal. "Although I am very tired, I am happy. I am a community worker and a Communist party member. I have had experience in fighting SARS before. The country is in trouble, and it is the responsibility of every man. I volunteered to join the fight against the epidemic and contribute my strength to winning this defense war. " Wang Jinrong said.

Multi-pronged approach to ensure the "two mistakes" in resuming work and epidemic prevention work

There are 4,715 households and 10,077 people in Pingyang Road Second Community, Yingpan Street, xiaodian district, Taiyuan, Shanxi. During the epidemic prevention and control period, Pingyang Road No.2 Community mainly carried out joint prevention and control work from four aspects.

First, attach great importance to epidemic prevention and control to ensure that responsibilities are put in place. Immediately after the outbreak of the epidemic in COVID-19, Pingyang Road No.2 Community set up a leading group for epidemic prevention and control, headed by the secretary of the community party committee, with community workers as the main members, to ensure that the responsibilities are clear to everyone. Second, do a good job in epidemic prevention and control propaganda. According to statistics, during the epidemic prevention and control period, 50 epidemic prevention propaganda banners were hung in Pingyang Road No.2 Community, and more than 2,000 posters were posted to strictly investigate 15 kinds of epidemic-related illegal and criminal acts during the epidemic prevention and control period. At the same time, 19 mobile audio systems were set up to carry out epidemic prevention propaganda in the streets and alleys of the jurisdiction to achieve full coverage. Third, do a good job in the registration of foreign personnel. Pingyang Road No.2 Community conducted in-depth and detailed investigations, and made statistical reports on returnees and close contacts from Hubei and overseas; For the returnees from Hubei and overseas, we will inform the precautions point to point by telephone communication, require detailed information, sign the responsibility letter and report it to the sub-district office in time, do a good job of body temperature monitoring twice a day, build a ledger, and carry out the telephone follow-up work of "looking back" in time. For returnees from other areas, "one household, one form" registration is required, and it is required to fill in the commitment letter of home isolation, carry out body temperature test and handle the registration certificate before entering the community. Fourth, do a good job in epidemic prevention and control in shopping malls, farmers’ markets and stores. During the epidemic prevention and control period, Pingyang Road No.2 Community gave full play to the role of street leaders, cooperated with xiaodian district Municipal Market Supervision Administration to strengthen the management of farmers’ markets and stores, and supervised the establishment of temperature monitoring accounts and the implementation of daily disinfection system in stores that resumed work.It also banned the sale of live poultry in farmers’ markets, and urged shopping malls, hotels, restaurants and farmers’ markets to implement measures such as ventilation, disinfection and body temperature monitoring.

After the comprehensive resumption of work and production, Pingyang Road No.2 Community took the initiative to fully ensure the effective implementation of various prevention and control measures. By setting up a centralized service platform for returning to work and production and setting up a service point for returning to work and production in the community party-mass service center, we will answer questions for enterprise employees and individual industrial and commercial households and register them for the record. Around the three major links of production, sales and circulation, a service group for returning to work and production was set up, and door-to-door visits were made to re-examine and re-verify the activity tracks of 528 merchants and employees in the area within 14 days, and actively coordinate and solve the problems and difficulties existing in the process of returning to work and production. In order to enable enterprises and merchants to fully obtain policy information, Pingyang Road No.2 Community has adopted a combination of centralized publicity and key publicity to carry out all-round publicity on policies related to the resumption of work and production. In view of the fact that some enterprises and businesses do not have complete epidemic prevention materials, we will actively connect with streets and relevant departments, provide enterprises and businesses with channels and resources for purchasing epidemic prevention materials, assist businesses and businesses to implement epidemic prevention measures, and ensure that the resumption of work and epidemic prevention work are "correct".

Work together to build an "epidemic-free community"

Qingheju Community is located in Qingshan District, Wuhan City, Hubei Province. As a public rental community, there are more than 8,000 permanent residents in the community, showing the characteristics of "three more" in general: many elderly people, many disabled people and many low-income groups.

Workers in Qingyou Xili Community, Nanshi Street, Heping District, Tianjin are clearing snow and ice.

Since the outbreak, on the one hand, Qingheju community has given full play to the institutional advantages of "three-way linkage", rationally divided labor and supplemented each other. Schwab Property, a community property service enterprise, fully cooperates with the community neighborhood committee to do a good job in door sealing, temperature measurement, disinfection in public areas, water and electricity security, etc., and heightens and closes the low walls and street windows to ensure that the virus is isolated outside the community. Community workers do a good job in mass guidance and household surveys, carry out actions to care for the disadvantaged groups, and respond to the concerns of the masses in a timely manner while solving the basic living problems of the masses.

On the other hand, at the most aggressive stage of epidemic prevention and control, Qingheju community has also implemented two levels of prevention and control, with the property service enterprise responsible for the gate of the community, and mobilizing community grid workers and volunteers to carry out building sealing and control, which not only prevents disorderly gathering, but also accurately registers people’s demands and solves them in time.

Facing the severe epidemic situation in Wuhan, Qingheju community launched several fronts to "fight" at the same time and tried its best to ensure the health and safety of residents. Community grid workers give up their rest time, stick to the community every day, and patiently publicize, guide and explain the epidemic prevention and control policies. The staff rate of property service enterprises is nearly 90%. While ensuring basic property services, they complete a large number of temporary tasks such as disinfection and sealing, and assist the community in transporting and distributing people’s daily necessities. In addition, the property service enterprises actively set up non-contact delivery areas and sole disinfection areas in the community to provide basic guarantee for joint prevention and control work in the community. Community volunteers, composed of cadres of sinking organs and community residents, actively contribute and cooperate with communities and property service enterprises to jointly do a good job in joint prevention and control.

In the survey and evaluation of property service satisfaction rate during epidemic prevention and control conducted by Wuhan Housing Security and Housing Administration, the satisfaction rate of Schwab property owners reached 99.49%. It is understood that on March 20, Qingheju Community successfully declared the "epidemic-free community".

"four in place" to build a solid barrier to prevent and control epidemic situation

Xiangmin Community, Xiufeng Street, Kaifu District, Changsha City, Hunan Province, is a new urban community serving newly-built buildings and units in the urban-rural junction area of Changsha. Since January 23, Xiangmin community has implemented the responsibility system of all-in-one responsibility, achieving "four in place" and building a solid barrier to prevent and control the epidemic.

The main entrance and exit of Qingheju Community in Wuhan City, Hubei Province is closed.

First, the investigation is in place. Organizing investigation is the first task of community epidemic prevention. In order to ensure the orderly entry and exit of residents, Xiangmin community promptly mobilized the strength of property service enterprises, industry committees, party member, volunteers, etc. According to the principle that each community cadre is entitled to one piece, 8 to 10 people are responsible for the inspection of each piece, and the returning personnel are checked and registered to ensure that "no one is missed". From January 23rd to February 8th, Xiangmin Community has carried out four "carpet-style" investigations, with a total of 7,038 households, 254 stores, 8 enterprises, government agencies and units, and 184 people returning from Hubei.

Second, publicity is in place. From January 27th, Xiangmin community launched a large-scale epidemic prevention publicity to ensure that the masses can "see". Record epidemic prevention and control knowledge, open letters, proposals, etc. into audio publicity materials, and record epidemic propaganda knowledge into allegro form, and use community speakers to play it circularly to ensure that the masses can "hear". At the same time, compile a small video and send it to the community WeChat group to let the people "remember".

Third, supervision is in place. In the early "epidemic prevention war", Xiangmin community mobilized all available forces and organized all kinds of backbone forces in the community to act as voluntary disinfectors, supervisors and persuaders, giving full play to and embodying the role of community autonomy. It is understood that Xiangmin Community mobilized 42 party member from the Party branches of five property service enterprises within its jurisdiction, set up five party member assault teams, and launched an industry committee, 32 building directors, 3 social organizations, 232 members of social organizations and volunteers to fight the epidemic together. In order to ensure the daily life of isolated families at home, the party member assault team is responsible for purchasing and distributing living materials to the door in all communities, ensuring that isolation measures are in place and residents in the communities feel at ease.

During the epidemic prevention and control period, the elderly and children are the two groups that are most concerned, and the Xiangmin community has carried out the "one old and one small" caring activities in an orderly manner. On the one hand, we sent disinfectant, masks, alcohol and other epidemic prevention materials as well as daily necessities such as fruits, vegetables, rice and oil to 34 elderly people living alone and with mobility difficulties in the area to ensure their basic livelihood. On the other hand, in order to ensure the mental health of children in the community during the epidemic prevention and control period, Xiangmin Community cooperated with community workers and volunteers to carry out a series of online activities, such as a family education lecture on "grandparents’ parenting room" and a collection of paintings and calligraphy works on "children’s hearts drawing together to fight the epidemic".

Up to now, there is no case of living difficulties in Xiangmin community due to the epidemic situation, and there is no case of mass riots in the community. Enterprises, institutions and construction sites in the area have resumed work in an all-round and orderly manner, and the rate of stores in the area has reached 95%.

Response to the epidemic: China blocked nearly 60 million people and other countries may not be able to achieve it.

On the evening of January 30th, local time, Tedros Adhanom Ghebreyesus, Director-General of the World Health Organization, held a press conference in Geneva, Switzerland, explaining that the pneumonia epidemic in novel coronavirus has constituted a "public health emergency of international concern". Tedros Adhanom Ghebreyesus stressed that WHO does not approve or even oppose a travel or trade ban on China.

Since the outbreak, the international community has paid close attention to it. China’s response has won praise from the world, and countries have acted quickly to overcome the difficulties.

The China system is very effective.

"The challenge is enormous, and China’s response is impressive." According to the BBC website, Michael Ryan, Executive Director of WHO Health Emergency Project, praised China’s response to the novel coronavirus epidemic.

CNN said that the China administration’s response to the epidemic was unprecedented and may not be realized in other countries — — China has imposed a blockade on nearly 60 million people and imposed full or partial travel restrictions on more than a dozen cities in Hubei Province. Major cities have launched the highest level of emergency response, set up checkpoints on roads, and screened passengers at airports and railway stations … … CBS reported that China launched an all-out campaign to fight the epidemic. Doctors treated patients day and night, and the military arrived in Wuhan to provide material support.

Spain’s "National News" website noticed that in Wuhan, a hospital was completed in less than 10 days, and the second emergency hospital also started construction.

"The China system is very effective in a crisis situation. It can take measures that require strong human and material resources and a well-functioning hierarchical system. " In an interview with the German newspaper Le Monde, China of Bertelsmann Foundation and bernhard Barchi, a senior expert in the Asia-Pacific region, commented on China’s initiative.

Zhou Rui, chairman of the French "Bridge" think tank and an expert on emerging economies, pointed out that at a critical juncture, China chose to close almost the whole of Hubei Province — — Almost equivalent to the size of France — — It has protected all countries in the world from the greater intrusion of the epidemic.

The World Health Organization praised that China has always adhered to the principle of openness and transparency, released information in a timely manner, quickly identified viruses and shared gene sequences, and adopted decisive and effective measures to control the spread of the epidemic, which not only reflected a high degree of responsibility for the lives and health of its own people, but also strongly supported global disease prevention and control.

Open and transparent to overcome the difficulties

In addition to taking extraordinary measures to prevent the export of cases, China identified pathogens at an unprecedented speed and shared the relevant virus gene sequences with the World Health Organization and other countries for the first time, which made it possible to develop a rapid virus detection tool.

According to Reuters news, the Russian Consulate in Guangzhou revealed that Russia and China are cooperating to develop a coronavirus vaccine.

According to the website of the Sydney Morning Herald, Australian scientists are the first to cultivate novel coronavirus outside China, hoping that this breakthrough will speed up diagnosis and help vaccine research and development. According to the report, it is expected that the cultivated virus will be used for antibody detection, so that the virus can be detected when the patient has not developed symptoms and therefore does not know that he is carrying the virus. It will also be used to test the effectiveness of experimental vaccines.

The Financial Times website reported that in China, Clover Biopharmaceutical Company plans to develop a vaccine based on the key protein in coronavirus, and put a candidate vaccine into trial in just a few weeks. The goal of the Oslo-based Innovation Alliance for Epidemic Prevention is that at least one candidate vaccine that can prevent coronavirus infection can be put into the first phase of clinical trials within 16 weeks to test the human tolerance to it.

"The search for vaccines benefited from the decision of the China government to release detailed information of coronavirus as soon as possible, which enabled scholars and pharmaceutical companies around the world to study its genome sequence." The Financial Times website pointed out. Russian newspaper quoted Russian officials and experts as saying that China showed unprecedented openness, which greatly helped disease research. According to the Guardian, compared with the SARS period, China is developing in a more open direction.

Take the initiative to ease concerns.

Whether the epidemic will have an impact on the world economy in 2020 has aroused widespread concern.

In an article published on January 30th in The New York Times, USA, "The world quickly realizes how dependent it is on China", it is pointed out that now, Japan is preparing for possible shocks, and the Federal Reserve is "closely watching" the changes in the situation. As the world’s largest source of tourism revenue tightens its borders, hotels and travel agencies all over Asia are worried.

However, many people remain optimistic. The article on the website of the Financial Times pointed out that no epidemic has caused a long-term reversal of market trends. The market rebound in 2003 was swift and violent. The global stock market rose by nearly 30% for the whole year.

Jennifer mckeown of the London Consulting Group also believes that the global economic growth in the second quarter of 2003 dropped by a full percentage point due to the epidemic of SARS. However, it quickly made up for the fundamentals of the economy, and it is difficult to list any lasting damage caused by SARS to global economic activities and global GDP.

China’s initiative has also eased the world’s worries. CNBC, an American financial website, said that after China took stricter measures and set up a high-level leading group, investors’ panic seemed to be ebbing. Bank of America, an investment bank, said that in the new crisis, China has been more proactive in updating the situation. To some extent, China’s response eased the concern that the epidemic might have a serious global impact.

The world has confidence in China. As Singaporean Foreign Minister Wei Wen said, compared with the fight against SARS in 2003, China’s technology, experience and ability to meet such challenges have been significantly improved. New Zealand is full of confidence that China will finally defeat the novel coronavirus epidemic.

Dr Jeremy Faller, chairman of Wellcome Foundation and an infectious disease expert, said: "China is setting a new benchmark for the response to the epidemic, and we should thank China." (Reporter Zhang Hong)

CCTV unveiled the current situation of genetically modified rice in the market.

In April this year, the reporter randomly bought five bags of different varieties of rice in a large supermarket in Wuhan, Hubei Province, and then sent them to the China Academy of Inspection and Quarantine for testing. The test results are surprising. Among the five kinds of rice, three contain genetically modified ingredients. So far, the government of China has never approved the commercial cultivation of any kind of genetically modified rice, nor has it approved the import of genetically modified rice, which means that the genetically modified rice and rice products appearing in the market are illegal, and these illegal genetically modified products are quietly coming to people’s table.

Transgenic component Bt63 was detected in the rice purchased in the supermarket.

In recent years, there have been media reports that the rice sold in the surrounding markets in Wuhan, Hubei Province contains genetically modified ingredients. At the same time, rice products exported from China to the European Union are frequently found to contain genetically modified ingredients. In the EU’s rapid warning system for food and feed, in 2013 alone, rice products exported from China to the EU were found to contain genetically modified ingredients for 25 times.

In April this year, the reporter bought five kinds of rice at random in a large supermarket in Wuhan, and then sent them to China Academy of Inspection and Quarantine for testing. The test results are surprising. Among the five kinds of rice, three contain the genetically modified ingredient Bt63, and most of the genetically modified ingredients displayed in the EU early warning system are of this type.

Bt63 is a patented transgenic insect-resistant rice developed by the School of Life Science and Technology of Huazhong Agricultural University. It was successfully developed in 1999 and has been evaluated for 11 years. In 2009, Bt63 transgenic insect-resistant rice obtained the safety certificate of transgenic organisms, but it was not approved for commercial planting. According to "People’s Republic of China (PRC) Seed Law", genetically modified crops are not allowed to be planted commercially before obtaining the commercial planting license. Then, where did the rice containing Bt63 gene detected in the market come from, where was it planted, and where did the seeds come from?

A kilo of rice is planted in 40 yuan, and many farmers grow insect-resistant rice.

Zhongshan Road, Wuchang District, Wuhan City is a famous seed street, where dozens of seed sales outlets, large and small, are concentrated. In April this year, during the rice planting season, the reporter came to this street, trying to find genetically modified rice seeds and then tracing their sources.

I heard that the reporter wanted to buy insect-resistant rice, but the owners of several shops said that they didn’t. When asked why, they said that they had sold it before, but now it is strictly controlled and no one dares to sell it.

After repeated questioning by reporters, a boss provided clues. According to this, the reporter went to Jinxing Village of Lingmiao in Jiangxia section for investigation, and found that many local farmers were planting genetically modified rice. They buy rice seeds at the seed sales point in Jinxing Village at the price of one catty in 40 yuan, but they usually buy rice seeds through acquaintances. For various reasons, the boss of the point of sale avoided the reporter’s interview.

The source of transgenic rice seeds may be Huazhong Agricultural University.

Bt63 transgenic insect-resistant rice is a patent of School of Life Science and Technology, Huazhong Agricultural University. Theoretically, Huanong is the original seed source of all the transgenic rice containing Bt63 in the market.

Zhang Qifa, academician of Chinese Academy of Sciences, professor of Huanong College of Life Science, mainly engaged in molecular genetics and genetic engineering research, and the leader of Bt63 transgenic insect-resistant rice project. In the interview, Zhang Qifa did not deny the possibility of GM rice spreading from Huanong. According to him, there may be two channels: first, different units or individuals may take rice seeds when the results are displayed and identified in 1999; Second, when Huanong conducted a large-scale productive experiment in 2003, a subsidiary may illegally breed after taking the seeds.

According to Zhang Qifa, in the 1990s, the state did not have strict legal provisions on the safety management of genetically modified organisms, and many scientific research achievements were shared by everyone. It was not until 2001 that the State Council issued and implemented the Measures for the Safety Management of Agricultural Genetically Modified Organisms that the safety management of genetically modified crops became standardized. Prior to this, seed companies could easily get Bt63 transgenic insect-resistant rice seeds, then breed them themselves and then enter the market.

According to several media reports, Zhang Qifa was the CEO of a company named corneal, which was the important source of Huanong’s "intentional disclosure" of genetically modified rice.

In this regard, Zhang Qifa said, "It is hard to say that it was intentionally leaked". At that time, the establishment of the company was a part of the country’s plan to promote the cultivation and industrialization of genetically modified crops. He introduced that according to the national regulations on the management of genetically modified crops, large-scale productive experiments must be carried out before genetically modified insect-resistant rice can obtain a biosafety certificate. In 2003, the Ministry of Agriculture approved 2,000 mu of farmland for the production test of Bt63 transgenic insect-resistant rice, in which hundreds of farmers participated. At the end of 2002, after the establishment of corneal Company, the production experiment of Bt63 transgenic insect-resistant rice was just completed.

So, in the process of productive experiment, did it cause the leakage and diffusion of seeds? According to Zhang Qifa, corneal Company didn’t have seed production capacity at that time, but entrusted other seed companies to produce seeds, and then distributed the seeds to farmers after recycling them. In this process, the seed company has the possibility of leakage.

The shopkeeper tore up the receipt and denied selling genetically modified rice seeds.

The reporter went to Wulijie Town, Jiangxia District, Wuhan, which is also a major rice producing area. According to the interview experience in Duanlingmiao town, it is difficult for strangers to buy genetically modified rice seeds, so the reporter found a local farmer to help him buy them at the seed sales point in the town.

According to the farmer, this kind of insect-resistant rice is very popular among farmers, because it can resist borers, and they can save the money for buying pesticides and the labor cost for spraying drugs, saving 200 to 300 yuan per mu, which is quite attractive to farmers with a gross income of only over 1000 yuan per mu.

There are nearly ten seed shops in Wulijie town, large and small, and the farmers who help them enter a sales point called Jiexing Seed Shop. A few minutes later, the boss turned into the back room and took out two bags of genetically modified insect-resistant rice seeds. However, when the reporter entered the salesroom again, the proprietress said that she never sold genetically modified insect-resistant rice seeds.

Subsequently, the reporter sent the purchased rice seeds to Beijing Entry-Exit Inspection and Quarantine Bureau for testing, and the results showed that the rice seeds contained insect-resistant transgenic Bt63. According to the information on the packaging of the rice seed named "Liangyou Jianghui 902" purchased by the reporter, the rice seed was produced by Hunan Xiuhua Technology Co., Ltd. The reporter went to Xiuhua Company in Zhuzhou City, Hunan Province, and found Li Yonghong, the person in charge of declaring the variety at that time, but he said that the company could not have genetically modified seeds.

With the assistance of Zhuzhou Seed Management Station, the reporter sampled the seeds of Liangyou Jianghui 902 on the spot. The test results showed that the sampled grains did not contain Bt63. That is to say, the seeds purchased by the reporter in the seed sales department in Jiangxia District of Wuhan and the seeds in the grain depot of Hunan Xiuhua Company are not the same rice seed.

Then, who produced the genetically modified rice seeds purchased by reporters and how did they enter the market? The reporter once again came to Jiexing Seed Sales Department. The proprietress denied that she had ever sold rice seeds, so the reporter took out the receipt issued by the sales department when she bought rice seeds, but the proprietress always denied it. Under the stalemate, the reporter dialed the complaint phone number of Jiangxia Seed Station marked on the receipt, hoping that law enforcement officers could come to investigate and collect evidence, but the person who answered the phone said that the leaders had a meeting and the law enforcement officers had gone to the countryside and could not come.

No sooner had the reporter put down the phone than the owner of this shop appeared. After a dispute, the boss tore up the receipt and drove the reporter away.

Rice testing loopholes, factory inspection, genetically modified

Among the three kinds of rice bought by the reporter that were found to contain transgenes, two kinds of rice were produced at Shekou Street in the urban-rural junction of huangpi district.

According to Director Ni of a rice factory, the rice provided by the reporter should come from Jianghan Plain, such as Qianjiang, Jingmen and Jingzhou. The rice and rice in their processing plant come from all over the country. During the processing, the factory will make certain preparations according to the taste and color of the rice, and then pack it and leave the factory.

In the test report presented by director Ni, the reporter saw that the rice in Wuhan market is currently implemented in GB1354-2009 standard. The standard only stipulates some physical indicators of rice. After the local regulatory authorities test rice according to this standard, qualified rice can enter the market for sale.

It is understood that the rice factory standards formulated in China do not contain genetically modified detection items, so government regulatory authorities and enterprises will not test the rice factory, which leads to rice manufacturers not knowing even if some rice contains genetically modified ingredients. These rice, so quietly to the consumer’s table.

For many export enterprises, they also face the same problem, because they unknowingly bought rice containing genetically modified ingredients, which caused them to suffer losses when exporting. A batch of white rice cakes exported by a food company in Shanghai to the European Union in 2013 were found to contain genetically modified ingredients.

In order to reduce losses, some domestic enterprises will conduct their own testing of genetically modified ingredients according to EU standards. However, the general manager of a food company in Shanghai said that because there are many sources of rice in the market, despite the testing links, enterprises are hard to prevent. According to what they know, genetically modified rice has spread, and it is difficult to recover it, and it is out of control. Most of the rice in Hunan, Hubei, Anhui and Fujian have been "polluted" by genetic modification.

It is understood that on May 27 this year, the Ministry of Agriculture issued the Notice of the Ministry of Agriculture on Further Strengthening the Safety Supervision of Agricultural Genetically Modified Organisms, requiring agricultural departments at all levels to focus on rice, corn, soybean and rape seeds and severely investigate and deal with illegal production, processing and sales of genetically modified seeds according to law.

A comprehensive breakthrough in "localization"

Under the leadership of Su Yongqiang, Shen Gu survived the most difficult stage in history and finally turned the corner.

In January 2006, at the national science and technology conference, the national leaders formally put forward the policy of "independent innovation". A month later, the State Council issued "Several Opinions on Accelerating the Revitalization of Equipment Manufacturing Industry" (the State Council No.8 Document in 2006), which proposed that "we should select a number of major technical equipment and products that have an important impact on national economic security and national defense construction, have a significant effect on promoting the sustainable development of the national economy, have a positive driving role in structural adjustment and industrial upgrading, and can expand the market share of independent equipment as soon as possible, and increase policy support and guidance to achieve major breakthroughs in key areas."

Among the 16 key breakthrough areas listed in this document, two are directly related to Shengu, namely, the localization of large-scale ethylene complete sets of equipment of one million tons and the research and development of large-scale coal chemical complete sets of equipment. The transformation of the country’s major policies has provided conditions for the all-round breakthrough of Shen Gu.

Text | Lu Feng Wang Chen Guo Nianshun Peking University School of Government Administration

Editor | Xie Fang looks at the think tank

In order to reprint the original articles of Wangzhi think tank, please indicate the source of Wangzhi think tank (zhczyj) and the author’s information before the article, otherwise the legal responsibility will be strictly investigated.

one

"Localization" has finally entered the room.

While China’s 300,000-ton ethylene equipment has not been made in China, the international ethylene equipment continues to develop to a large scale, and a million-ton ethylene plant was built in the second half of 1990s. After entering the 21st century, China has also built three million-ton ethylene projects with the international trend, namely, the 900,000-ton ethylene project of Shanghai Secco Petrochemical Co., Ltd., the 800,000-ton/year ethylene project of China Shipping Shell, the 10,000-ton oil refining project of Dushanzi Petrochemical Company of PetroChina and the 1,000-ton ethylene project. However, they all did not use domestic main equipment because of joint ventures and other reasons.

Shengu Group. Figure | Figure worm creativity

At that time, excessive dependence on imported equipment has become a stumbling block to the development of petrochemical industry in China. In a report to the National Development and Reform Commission, Sinopec wrote: "In recent years, the shortage of international special equipment and materials resources has brought great pressure on the supply of equipment in the domestic petrochemical industry. For example, the supply of large-scale units such as ethylene’ three machines’ (cracking gas compressor, propylene compressor and ethylene compressor) is very tight in the global market, and some foreign manufacturers often do not respond to domestic inquiries. The delivery time has been extended from 12 months in 2003 to 22-24 months in 2007, and the price has nearly doubled. "[1].

Obviously, if the equipment is not localized, the petrochemical industry in China, which has entered a high-growth track, will be curbed.

The first self-built million-ton ethylene project in China was the 1 million-ton/year ethylene reconstruction and expansion project of Maoming Petrochemical Company, which was formally started in December 2004 and completed in September 2006. It was based on the 360,000-ton/year ethylene project of Maoming Petrochemical Company. According to the report on the website of SASAC, "448 of the total 510 cracking units in the project are made in China, and the localization rate of the equipment is 87.8%. Not only the new technology of ethylene cracking and ethylene recovery jointly developed by China Petrochemical and Rhuems Company of the United States is adopted, but also some core equipment such as ethylene cracking gas compressor and cold box are localized." [2] The cracked gas compressor mentioned in this report is provided by Shen Gu, but at the enterprise level, the actual situation is not so "politically correct".

When Maoming Petrochemical signed a contract with Shen Gu, the venue ready for signing had been arranged. The boss in charge of technology of the other party took Su Yongqiang and said, let’s have a talk outside. Su Yongqiang asked him, "We have to sign this time. What’s your attitude now?" The other party said, "I still agree to import." When Sue asked why, he said, "Manager Su, you have to understand me. I know that you are capable and you can do well, but if you say it from my mouth, my head will be smashed." Most of the risks are understood, and the deeper reasons are not mentioned. You can sign if you have the ability, and I will serve you if you sign. " Su Yongqiang said he would sign it right away, but he still didn’t believe it. Of course, Su Yongqiang signed it-"Maybe I’m a competitive person, and I have to do what I can’t do."

Su Yongqiang.

The major turning point of "localization" is the establishment of the national policy of independent innovation. In June, 2006, according to "Several Opinions on Accelerating the Revitalization of Equipment Manufacturing Industry", the million-ton large-scale ethylene complete equipment was listed as the key point of localization by the National Development and Reform Commission. At that time, the localization rate of ethylene plant, PTA complete sets of technical equipment and natural gas long-distance pipeline equipment was required to be not less than 75%.

In this context, China decided to invest 20 billion yuan in Tianjin, Zhenhai and Fushun to build three million-ton ethylene projects, and gave Shengu Group the task of supporting "three units". However, to be on the safe side, the million-ton ethylene "three machines" developed by Shengu for the first time were not put into the same project, but were respectively assigned to three million-ton ethylene plants, namely, Sinopec Tianjin Petrochemical used cracking gas compressor, Sinopec Zhenhai Refining and Chemical Company used propylene compressor, and Fushun Petrochemical Company under PetroChina used ethylene compressor.

When Su Yongqiang took the "Shangfang Sword" (that is, the task assigned by the government department) to find the main leaders of the party group of big users, they still said that it was best to ask Zhang Guobao, deputy director of the National Development and Reform Commission, to sign it. Su Yongqiang still remembers what Zhang Guobao said to him: Lao Su, I am the deputy director of the National Development and Reform Commission, and I have never signed for the enterprise. But you are special, and you are promoting localization. Although Deputy Director Zhang Guobao hesitated, he finally signed it on the spot. To put it bluntly, it is still risky, otherwise the project can be decided between enterprises.

People in petrochemical companies told Su Yongqiang that the value of one-time feeding of a million-ton ethylene plant is 160 million yuan. If there is something wrong with the "three machines" of ethylene, all the plants have to stop and all the raw materials of 160 million yuan have to be released. How many compressors do you have to buy? By May, 2007, all parties signed the contract, and Shengu Group began to undertake the research and development tasks of cracking gas compressor, propylene compressor and ethylene compressor of the million tons/year ethylene plant.

2

Break through the core technology again

In fact, Shen Gu has been preparing for the development of million-ton ethylene "three machines" for a long time, and has invested tens of millions of yuan in research and development expenses before getting the contract. Compressor is a customized large-scale complex product system. Without the application of specific engineering, it is of little significance to make an independent prototype. Therefore, Shen Gu’s product development is basically combined with engineering projects, that is, it is put into product development when there is an order. However, the research and development of related technologies for new products has actually started.

An important prerequisite for realizing large-scale equipment is the breakthrough of core technology. For the compressor with heavy drum, the first key technology is impeller. The large-scale compressor brings many practical problems: the reliability of large-size impeller operation, the quality problems caused by welding deformation, defects and thermal stress, and the corrosion of defective parts under bad working conditions.

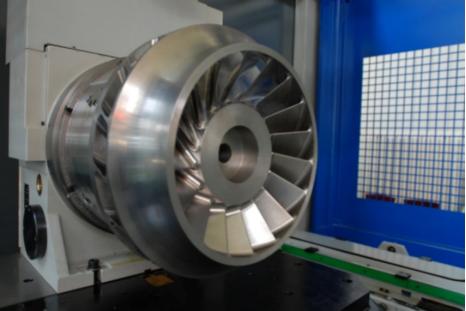

In 2005, the R&D team headed by Cui Lianshun (female) began to develop the integral milling impeller that only GE mastered at that time. Integral milling impeller has attracted much attention because it is much better than welded impeller in material utilization rate, machining efficiency, machining quality and corrosion resistance, but the process of integral milling is very difficult. First of all, to process the general outline of the impeller on an extremely expensive low-temperature steel, even rough machining requires extremely fine requirements. The position of the first knife is particularly critical, and the whole blank may be scrapped if it is not careful. The tool used is a harder material than the billet, and the redundant part is removed one minute at a time during rotation. Then, this rough machined part is sent to the CNC milling machine for the most critical overall milling, and the straight cutter will mill spiral blades on this whole billet. This is an extremely complicated procedure, and the slightest error will make the whole project go to waste.

Integral milling impeller fixed on milling machine.

After two years’ efforts, Cui Lianshun’s team successfully developed a three-dimensional closed impeller with integral milling in May 2007, making Shengu one of the only two enterprises in the world to master this technology at that time. The maximum diameter of the impeller with integral milling is 1500mm(1.5 m), which has reached the advanced level in the world.

After 2007, Shengu continuously broke through the million-ton ethylene compressor, long-distance pipeline compressor and large air separation compressor because of the application of large-scale integral milling impeller technology. With this technology research and development as the foundation, Shengu has always maintained an outstanding record of "if you do it, you will succeed" in those large projects that adopt the first set of equipment.

three

The Battle of "Million Tons of Ethylene"

The foundation stone was laid in June 2006 for the million-ton ethylene project of Tianjin Petrochemical Company, and it was officially put into commercial operation in May 2010. The first million-ton cracked gas compressor developed by Shengu for this project was installed in June 2009. When this unit is appraised at the factory, the appraisal meeting will end in 20 minutes. Usually, this meeting will last at least two hours. Then why did it only last for 20 minutes? Because all the data displayed in the instrument are advanced, there is no question to ask after reading the report, and it will be passed directly.

Finally, the relevant leaders made a summary, saying that all indicators showed that this unit was an excellent one. He talked about an experience: after dealing with Shen Gu for so many years, our greatest experience is the enterprise characteristics of Shen Gu: as long as it is a difficult bone, a complex, risky and technically complex project, Shen Gu will certainly win it.

There is another episode. When this million-ton ethylene cracking gas compressor was tested in Shengu, Sinopec invited an expert from Mitsubishi Heavy Industries of Japan to verify it. This is because the only enterprise that can produce this kind of large centrifugal compressor in China is Shen Gu, so no experts other than Shen Gu can do third-party certification. Su Yongqiang was at the scene. Japanese experts carefully watched the whole experimental process of Shen Gu without saying a word, and looked at the data. After all the tests were finished, the leader of Sinopec asked the Japanese expert about his skills, but he still didn’t say anything, just raised his thumb-a world-class level.

Shengu is the cracking gas compressor unit provided by Sinopec Tianjin Petrochemical Company for the million-ton ethylene project.

Sinopec Zhenhai Refining and Chemical Company’s 1 million tons/year ethylene project started in November 2006 and was completed and put into operation in April 2010. Shengu developed the first million-ton propylene compressor unit in China. Both propylene compressor and ethylene compressor are refrigeration, and their working environment is low temperature (propylene is generally used for refrigeration users at -50~0℃).

Zhenhai Refining & Chemical Company, as a user, requires that all partitions of Shengu compressor should be designed and manufactured with low-temperature resistant plates or forgings. In order to reduce the impeller diameter of the unit as a whole, Shengu adopted a high-efficiency three-dimensional impeller with large flow coefficient, high energy head and high Mach number, which was newly developed by R&D department and verified by performance experiments. Since then, Shengu propylene compressor unit has continuously passed the six levels of product design, large-scale casing assembly welding, impeller milling, rotor high-speed balance, mechanical operation test and performance test, and passed the factory acceptance of Sinopec Acceptance Committee in May 2009.

The acceptance experts agreed that the performance index of the propylene compressor unit in the million-ton ethylene plant reached the requirement of the technical agreement that the power deviation of the whole unit should not be greater than 2% of the design power, and the overall technical level reached the international advanced level, breaking the situation that this kind of products depended on imports for a long time.

The ethylene compressor is the last breakthrough in the development of ethylene "three machines" in Shengu. Ethylene compressors are generally used for users of cryogenic separation (-102~-60℃), and Shen Gu didn’t wait until 2006 to develop ethylene compressors for the first time. At that time, Huajin Group in Panjin handed over the order of ethylene compressors for the 450,000-ton/year ethylene expansion project to Shen Gu.

The leading designer of this project is Jiang Yan, a female engineer born in 1973. Without this kind of compressor development experience and external technical knowledge sources, Jiang Yan team worked hard and put in 3 years’ efforts to produce the products. However, this unit, which was put into trial operation in the factory, encountered the problem of excessive vibration as soon as the production line of Huajin was turned on. The reason is that the operating condition of the factory is normal temperature, but it is ultra-low temperature when it is turned on. Jiang Yan and the team searched for technical defects one by one, and finally broke the core problem of rotor structure operating at ultra-low temperature, and realized the stable operation of the first domestic ethylene compressor on January 8, 2010.

The 800,000-ton/a ethylene plant of Fushun Petrochemical Company started construction in April 2009, and the design task of developing the first million-ton ethylene compressor in China by Shengu was also given to Jiang Yan. In this project, Jiang Yan once again showed the courage and creativity of the Shen Gu technical team who dared to go their own way.

The structure and manufacturing process of large-scale ethylene compressor are very different from those of conventional compressors, and the biggest technical problem is the gas charging structure. In order to improve the efficiency of the general compressor, when it is compressed to a certain temperature by several stages of impellers, the compressed medium must be cooled and then compressed. Jiang Yan thinks that if the million-ton ethylene compressor is designed according to this method, it is necessary to add multiple air ducts, which will inevitably divide one compressor into two, resulting in double cost and reduced efficiency.

During that time, Jiang Yan couldn’t eat or sleep, and his mind was full of gas flow field maps. By chance, a sample of a low-temperature rotor detonated her idea: isn’t ethylene at MINUS 100 degrees Celsius itself a refrigeration medium? There is no need to toss the gas inside and out at such a low temperature. After asking for instructions, she decided to adopt the method of filling gas in the cylinder in the million-ton ethylene compressor. However, it is a major change in the structure of the whole unit from adding gas into the cylinder to adding gas into the cylinder. How to optimize the gas flow field without external gas addition, make the two gas additions not interfere with each other, improve efficiency and reduce the difficulty of casing processing, etc., involves the whole production process such as design, technology, processing and manufacturing. And all these problems, Jiang Yan must be solved one by one in the design process of product production source.

Jiang Yan has been cornered many times, and it often took days and nights to design the structure, but it was rejected because of a small defect. However, she and her team didn’t give up. When a structure was rejected, they carefully studied what they could learn from and applied it to the next scheme. In this way, with little accumulation and little improvement, Jiang Yan team perfected the structural design scheme of the unit in constant self-denial. At the same time, they have done a lot of basic research, from rotor dynamics to fluid mechanics to model-level development, constantly calculating every detail of simulating gas flow. After repeated argumentation and simulation, they finally formed a perfect design scheme for filling gas in the compressor cylinder. Practice has proved that the in-cylinder aerated structure greatly improves the performance and efficiency of the product, which is better than foreign units in some aspects [3].

The ethylene compressor should not only meet the strength requirements of the machine, but also improve the efficiency. By optimizing the design of the rotating parts such as the impeller, the Jiang Yan team successively overcame the difficulties such as the rotor structure, and finally formed a perfect design scheme for the million-ton ethylene compressor.

On the evening of February 22nd, 2011, the first million-ton ethylene compressor set in China was successfully tested in the assembly workshop of Shengu Group. In October 2012, Fushun Petrochemical’s 800,000-ton ethylene production plant was completed and put into operation. Since then, Shengu Group has successively signed several large-scale ethylene projects such as Wuhan, Yanshan, Huanggang and Zhenhai, and Jiang Yan team has designed and manufactured 16 ethylene compressor units in three years.

With the continuous success in developing the first set of equipment, Shen Gu is more and more trusted by users. In August, 2011, Sinopec Group and its affiliated Wuhan Branch packaged the products at one time, and delivered the orders for 8 centrifugal compressor sets, 5 reciprocating compressor sets and 4 pumps for the 800,000-ton/a ethylene project in Wuhan to Shengu. The total contract amount exceeded 300 million yuan, including the complete design and manufacture of all ethylene "three machines".

In 2013, Sinopec Wuhan 800,000-ton ethylene project was completed and put into operation. For the first time, Shengu became the general contractor of the million-ton ethylene "three machines". This is a great success, which proves that Shengu has become the mainstream supplier of ethylene "three machines".

In July 2013, the second phase of CNOOC Huizhou Refining and Chemical Company started construction, which is a project to build 10 million tons/year oil refining and 1 million tons/year ethylene on the basis of the first phase of 12 million tons/year oil refining, and it is also the first refinery in the world to centrally process heavy crude oil with high acid content. Its 1.2 million tons/year ethylene production facility was the largest in China and the most advanced in the world at that time [4]. In September 2014, CNOOC signed a contract with Shengu to provide all ethylene "three machines" for Huizhou Refinery Phase II project. In April 2018, CNOOC Huizhou Refinery’s 1.2 million tons/year ethylene plant produced qualified propylene and ethylene products.

So far, Shengu has become one of the top compressor manufacturers in the world.

Zhongsha (Tianjin) Petrochemical Co., Ltd. (formerly Sinopec Tianjin Petrochemical Co., Ltd.) decided to expand its capacity after 10 years of operation of its million-ton ethylene plant. In July, 2020, the nitrogen test run of the cracking gas compressor unit of the largest domestic ethylene plant with a capacity of 1.3 million tons/year, which was installed by Shengu Group, was successful once, and the mechanical performance parameters of the unit reached the high-quality level. The successful commissioning of the unit modification indicates that Shengu Group has been in the leading position in the world in the research, modification and installation of the million-ton ethylene compressor unit.

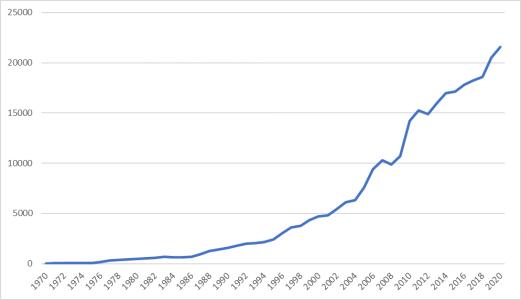

"Localization" is an important reason why China has made great progress in ethylene production: during the 30 years from 1975 to 2005, China’s annual ethylene production reached 6 million tons, and in the 15 years since the breakthrough of domestic equipment, China’s annual ethylene production reached about 21.6 million tons, and China became the second largest ethylene producer in the world after the United States.

Figure: Ethylene production in China from 1970 to 2020 (thousand tons)

Source: National Bureau of Statistics.

four

The Battle of "Long-distance Pipeline"

After the compressor of large-scale ethylene plant, another "localization" campaign of Shengu is the long-distance natural gas pipeline compressor, which should start from the "West-East Gas Transmission Project".

In February 2000, the first meeting in the State Council approved the start of the "West-to-East Gas Transmission Project", which is a great project in China’s energy field and the largest national project after the Three Gorges. Up to now, the "West-East Gas Transmission Project" has been divided into three stages, namely, West Line 1, West Line 2 and West Line 3. The general situation is as follows.

The West First Line Project was officially started in July 2002, passing through major provincial administrative regions such as Xinjiang-Gansu-Ningxia-Shaanxi-Shanxi-Henan-Anhui-Jiangsu-Shanghai, and was completed in 2004.

The West Second Line Project started in 2009, passing through major provincial administrative regions such as Xinjiang-Gansu-Ningxia-Shaanxi-Henan-Hubei-Jiangxi-Guangdong, and was completed and put into operation by the end of 2012. The West Second Line is the longest pipeline in China so far, with the highest pipeline steel grade, the largest pipe diameter, the largest gas transmission capacity and the greatest energy saving and emission reduction effect. The trunk line and branch line are all over 8,700 kilometers long, and the natural gas transported has entered the Yangtze River Delta and Pearl River Delta regions along the southeast coast through 15 provinces (autonomous regions and municipalities). If we add the foreign Central Asian natural gas pipeline, it can be said to be an "underground Great Wall of Wan Li Pipeline".

The West Third Line Project started in October 2012. The trunk and branch lines pass through 10 provinces and autonomous regions in Xinjiang-Gansu-Ningxia-Shaanxi-Henan-Hubei-Hunan-Jiangxi-Fujian-Guangdong. The total length of trunk lines and branch lines is 7,378 kilometers, which was completed in August 2014.

However, at the beginning of the "West-to-East Gas Transmission Project", it was also a major project relying on imported equipment. The pipeline of "west-to-east gas transmission" needs a lot of equipment, and the compressor is one of the key equipment, and it is the most important key equipment. The flow of natural gas in the pipeline depends on the power provided by the compressor, so it is necessary to build a pressurizing station every 200 kilometers and pressurize it with the compressor. The key equipment, including compressors, of the West First Line Project are all imported, and almost all of the West Second Line Project are imported. However, the only foreign enterprises that can provide pipeline gas compressors are GE, Rolls-Royce and Siemens.

Sui Yongbin, the chief engineer and consultant of China Machinery Industry Federation, was once the deputy director of the Ministry of Machinery Industry, and he was a man of lofty ideals who campaigned for the localization of major technical equipment for decades. According to his explanation: "The localization of China gas pipeline should not start from now. In the 1970s, the idea of "Sichuan gas flowing out of Sichuan" was put forward. In order to cooperate with "Sichuan gas flowing out of Sichuan", Chinese equipment manufacturers began to develop pipeline ball valves and compressors, and developed gas starters to drive pipeline compressors. For various reasons, the project was finally terminated. "

China decided to launch the "West-to-East Gas Transmission Project", which once again brought opportunities to China equipment enterprises. In Sui Yongbin’s words, "domestic equipment manufacturers have been waiting for opportunities since the beginning of the construction of the first line of the West-to-East Gas Transmission Project, hoping that the key equipment of the long-distance natural gas pipeline in China can use domestic equipment" [5].

However, this wait is nine years.

Shen Gu has been tracking since 1999, when the country was brewing the "West-to-East Gas Transmission Project". Since the first demonstration meeting of localization, Su Yongqiang has participated in 14 of the 16 demonstration meetings, and made speeches at the meeting every time, arguing with arguments, but failed to win a project.

The argument of west-to-east gas transmission is soul-stirring. Sometimes, people from Shen Gu didn’t get a chance to speak at the meeting, so the meeting decided to import it, and we will mention it domestically next time. Before this, Shen Gu did not make a gas pipeline compressor, but this kind of machinery is not complicated from principle to manufacture, and there is no insurmountable technical obstacle for Shen Gu. The problem is not technology-if domestic equipment is used, once problems occur, 500 million people will have no food. Who will bear the risk? Once the compressor is started, it will keep running for 365 days a year, and once an accident occurs, it will affect the overall situation.

[Note: The compressor unit used to be overhauled after 8000 hours of operation, but it was extended to one and a half years, then three years, and now it is overhauled every five years. 】

Even with heavy resistance, Shen Gu has been preparing for entering the long-distance pipeline market. In 2006, Shengu won the contract for the first "cooperative production" compressor, which was designed by GE and manufactured by Shengu. In 2007, I got a prototype, all designed and assembled by Shen Gu, but the prime mover (motor) and frequency converter were bought from abroad, and finally three finished products were made. Although Shen Gu failed to win an order for his compressor, when the country held a commendation meeting for the West-East Gas Pipeline Project, it still commended Shen Gu as an advanced unit and gave Su Yongqiang an outstanding individual. The award was signed by the the State Council West-East Gas Pipeline Leading Group.

Su Yongqiang asked the leaders of the National Development and Reform Commission, who presided over the meeting, how could we be awarded advanced without providing a single unit? The leader’s answer is: users said that although they didn’t give Shen Gu an order, Shen Gu’s intervention allowed them to beat foreigners with Shen Gu and saved them old money, so Shen Gu made great contributions to the country. Su Yongqiang said, "If you want to say so, I deserve it."

The substantial progress of "localization" of the "West-to-East Gas Transmission Project" occurred at the beginning of the construction of the West Second Line.

In April, 2009, the National Energy Administration held a meeting on "Localization of Key Equipment of Natural Gas Long-distance Pipeline" in Shenyang, and decided to carry out the localization research and development of "20MW electric drive compressor set", "30MW gas drive compressor set" and "high-pressure large-diameter welded ball valve" for the West Second Line Project.

Under the organization and coordination of the National Energy Administration, PetroChina took the lead in name, and Shengu developed a 20MW electric drive compressor unit, CSIC 703 developed a 30MW electric drive compressor unit, Shanghai Electric Group and Harbin Electric Group made motors, Anshan Rongxin Electric Power and SVA made frequency conversion, and five companies formed a company. In July 2010, the high-pressure large-caliber welded ball valve was successfully developed in Chengdu; In November, 2011, 20MW electric drive compressor set was successfully developed in Shengu. So far, the key technologies and equipment that restrict the long-distance natural gas pipeline in China have been successfully developed.

PetroChina paid experts from GE to certify the prototype of Shengu, and the result was excellent. Someone at the scene deliberately "provoked" and asked the experts of GE: What do you think of the comparison with the GE unit? The foreign expert replied that everything was fine, and even he was happy when he said it-in fact, he knew that the index of Shengu unit was better than GE.

However, although the policy of "localization" has been decided at the government level, and even domestic equipment has begun to be developed, there are still many obstacles to adopting domestic equipment at the implementation level. During the two years from 2009 to 2011, the debate on whether to adopt domestic equipment in the West Second Line Project has been in a state of "tug-of-war": it was approved at this meeting and overturned next time; After another meeting, it was decided to make it in China, and it was overthrown next time …

After several round trips, Sui Yongbin proposed to plan a cartoon, and Su Yongqiang found a professor from Shenyang Luxun Academy of Fine Arts to draw it. The professor drew several editions and passed them on to Sui Yongbin. Sui said that the painting was wrong and did not reach the artistic conception. Su Yongqiang discussed with Professor Lumei again, explaining to him that this is like tug-of-war, which is related to whether you win or I win.