() The business review of the Board of Directors in the first half of 2022 is as follows:

I. Main businesses of the Company during the reporting period

The company’s main business is to develop and sell professional and high-quality outdoor sporting goods, operate X-BIONIC black technology sports luxury brand, organize the group construction of outdoor sports events, design, construct and operate the comprehensive quality education project of "squirrel tribe parent-child outdoor paradise+eagle pole safety education and training+three-husband little warrior +SanfoHood wild luxury camp", and provide consumers with all-round products and services through the integration of various business sectors, encourage and help people to go outdoors, exercise healthily, and fully practice the life concept of harmonious coexistence between man and nature.

(a) the company’s industry

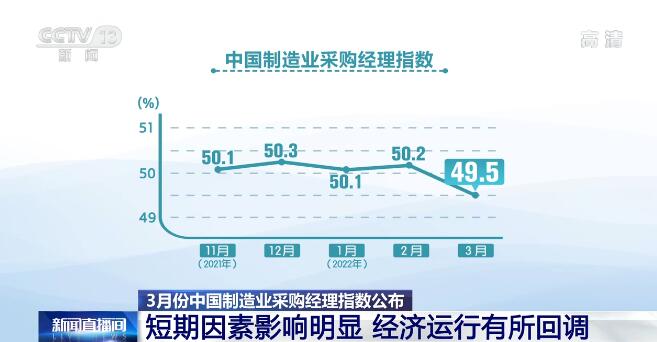

In the first half of 2022, the consumer market was greatly affected by factors such as frequent domestic epidemics. Statistics from the National Bureau of Statistics show that the total retail sales of consumer goods in the first half of the year was 21,043.2 billion yuan, down 0.7% year-on-year. Quarterly, it increased by 3.3% in the first quarter and decreased by 4.6% in the second quarter. According to the retail format, department stores and specialty stores in retail above designated size decreased by 8.4% and 4.1% respectively. The total retail sales of social consumer goods such as clothing, shoes, hats, and knitwear was 628.2 billion yuan, down 6.5% year-on-year. However, with the improvement of epidemic prevention and control situation and the effectiveness of promoting consumption policies, the consumer market has gradually picked up. In June, the growth rate of retail sales of most commodities rebounded, sales in some areas improved significantly, the operation of physical stores improved, and the consumer market showed an accelerated recovery trend.

In June, 2022, the 13th the NPC Standing Committee revised the Sports Law of the People’s Republic of China, which marked that the construction of China’s sports law entered a new stage, which was of great significance to standardize and lead the high-quality development of the sports industry in the new era and accelerate the construction of a sports power and a healthy China. In this revision of the new content, the contents of national fitness, strengthening teenagers’ awareness of physical fitness and promoting teenagers’ physical and mental health and physical fitness are highlighted; It is of great significance to adjust the economic structure of sports industry, increase employment, cultivate new economic growth points and meet the diversified sports needs of the people.

In July 2022, the General Office of the State Sports General Administration issued a work plan on sports to help stabilize the economy and promote the activation of consumption, aiming to promote the high-quality development of the sports industry, build a new development pattern, and contribute sports strength to stabilizing the economic market and ensuring the economic operation in a reasonable range. It is mentioned in the plan that offline sports events should be resumed in an all-round and orderly manner, and efforts should be made to ensure that domestic events should be done and broadcast, and more events should be presented to the people; Promote sports consumption, deepen the pilot work of sports consumption, and promote 40 national sports consumption pilot cities to better meet the sports consumption demand under the normalization of mass epidemic prevention and control by creating new sports consumption scenes, cultivating new sports consumption formats and models, issuing sports consumption vouchers, and organizing sports consumption festivals; Promote a green and healthy lifestyle, encourage people to go outdoors and participate in outdoor sports, and further tap the consumption potential in outdoor sports, green travel and other fields.

In May, 2022, the Sports Bank think tank released the "Report on the Development of Sports Industry in 2022", which holds that the outdoor sports industry is an integrated format with sports, tourism, culture and education functions. After the epidemic, it is expected to set off a new round of consumption boom, and it is expected to play a unique role in the strategy of "strengthening the country by sports in the 14th Five-Year Plan" and become a new growth point in the field of sports consumption.

In June, 2022, Taobao Tmall Sports Outdoor Industry and Taobao Education and Consulting Company Kearney jointly released the White Paper on Sports Outdoor Consumer Operation. The "White Paper" shows that after five years of development, product upgrading and usage scenario expansion, the number of outdoor sports users and the consumption of customers have maintained rapid growth. Looking at the scale of outdoor sports market in China, the compound growth rate will be around 13.7% in the next three years.

Under the background of epidemic situation, the related consumption promotion policies in the field of sports outdoor industry have been continuously introduced, and the concept of sports outdoor consumption has gradually risen to a part of the social cost of life. Under the multiple benefits of national policy support, public trend response and positive market feedback, the outdoor sports industry will show great market potential and strong development momentum.

(2) Main business of the company

In the first half of 2022, the domestic epidemic was frequently distributed, and the chain retail industry in which the company was located was greatly affected. The stores and other businesses under the multi-line were closed for some time, and the business segments of sports events, group building and parent-child youth were also subject to different degrees of business restrictions such as postponement, park closure and current restriction, which had a great impact on the company’s business activities in the first half of the year. Faced with the difficulties caused by the epidemic and the overall downward trend of the retail industry, all business segments of the company actively adjusted their business ideas, focusing on X-BIONIC product research and development, flagship store image design, brand marketing and CRM system construction, timely adjusting product structure and (or) product layout according to market demand, introducing interested e-commerce businesses such as Tik Tok and live broadcast, strengthening the IP of the event and the "Squirrel Tribe" parent-child outdoor park project, and concentrating on developing the life field and the construction of SanfoHood wild luxury camp in the parent-child interaction field.

In April 2022, the company increased its capital to hold Guizhou Yingji Sports Tourism Co., Ltd., which mainly focuses on comprehensive safety education for young people. Eagle Sports owns the brand of Eagle Sports Safety Education, and has been awarded many honorary titles such as "National Popular Science Education Base for Earthquake Prevention and Disaster Reduction", "Guizhou Popular Science Education Base for Disaster Prevention and Disaster Reduction", "Guizhou Youth Self-care and Self-help Training Base" by China Earthquake Administration, governments at all levels and superior units. It is an important part of the comprehensive quality education project built by the company in 2022, and the first demonstration base will be built in Nanjing.

During the reporting period, the company achieved an operating income of 236,941,400 yuan, down 4.84% year-on-year; The total profit was-12,224,400 yuan, a year-on-year decrease of 377.64%; Among them, the net profit attributable to shareholders of listed companies was-15,786,300 yuan, a year-on-year decrease of 1,165.12%. As of June 30, 2022, the company’s total assets were 1,069,700,700 yuan, and the net assets attributable to shareholders were 669,751,900 yuan.

1. Develop and sell professional and high-quality outdoor sporting goods.

(1) New retail operation

During the reporting period, the company has 47 direct chain stores in 18 cities across the country, representing and distributing more than 300 high-end professional outdoor sports brands at home and abroad. The products are divided into three categories: outdoor clothing, outdoor shoes and socks and outdoor equipment, covering skiing, camping, running, hiking, mountaineering, self-driving travel, urban commuting and many other outdoor scenes. Open comprehensive/brand flagship stores in Tmall, JD.COM, Mobile Micro Mall, Live Broadcast and other e-commerce platforms to provide consumers with professional and digital mobile shopping experience anytime and anywhere.

In the first half of 2022, the exquisite camping market exploded. Relying on the advantages of outdoor industry for many years, the company’s offline retail stores quickly organized and integrated the product structure, transformed and expanded the store camping area, enabled the experiential display mode, and transformed five large stores, including Beijing Huaxi Wukesong Store, Beijing Madian Zhongdian Store, Beijing Chaoyang Park Store, Shanghai Wanti Store and Shenyang Tianhui Plaza Store. The medium-sized stores also expanded the display of camping products, and the rich and diverse product structure allowed consumers to immerse themselves in many dimensions. The significant increase in the sales of camping equipment in offline retail stores partially offset the adverse impact of the epidemic on retail business during the reporting period.

The e-commerce team continued to focus on core brands such as X-BIONIC, dig deep into product selling points, improve product page quality, actively participate in promotional activities of Tmall and JD.COM platforms, and pay special attention to the improvement of users’ after-sales service experience, resulting in obvious business growth. Among them, the X-BIONIC online store adheres to the principle of "customer-oriented" and continues to maintain the high-speed growth momentum year-on-year. The X-BIONIC Tmall flagship store won the honor of "the new brand with the most powerful treasure", "the new brand with the most potential treasure" and "the annual dark horse award of global brand management mawards" from Tmall platform. In order to meet the needs of the rapid development of the company’s e-commerce business, combined with market changes and integration of resource advantages, the company established Sanfu Supply Chain Company, focusing on one-stop service of commodity warehousing, engaging in e-commerce cloud warehousing, warehousing custody, and promoting logistics solutions, and integrating "warehousing+order" processing into one professional warehousing logistics system, which laid a logistics foundation for the further development of e-commerce.

The new retail business continued to develop well. While maintaining the stability of Sanfu Outdoor Micro Mall, we made great efforts at the Tik Tok Live Track, opening Sanfu Outdoor Franchise Store and CRISPI official flagship store, achieving steady growth in the first half of the year. Among them, Sanfu Outdoor Micro Mall accumulated 8 million views in the first half of the year, with 170,000 visitors and a turnover of 8,542,600 yuan; Sanfu outdoor Tik Tok franchise store accumulated 350,000 visitors in the first half of the year, with a turnover of 6,087,200 yuan, achieving a breakthrough from zero to one million per month; CRISPI’s official flagship store officially opened in April 2022, and has achieved a turnover of 1.4 million yuan in the past three months, and it is growing rapidly. In the future, the company will continue to lay out interest e-commerce platforms such as Xiaohongshu and Aauto Quicker, build a traffic acquisition matrix, deeply promote the company’s brand, provide users with real value through high-quality scenes and experiences, and then realize efficient transformation.

(2) brand operation

1) own brand

During the reporting period, the company continued to increase its research and development efforts, improved the construction of various product lines according to different sports scenes, continuously enhanced the strength of its own brand products, and laid a solid product foundation for gaining greater market share.

Adhering to the concept of combining science and technology with advanced fashion, X-BIONIC continues to introduce high-quality products suitable for spring and summer, including various sun-proof windbreaker jackets, waterproof clothes and pants, many long and short-sleeved T-shirts with different functions, long and short-sleeved POLO shirts, running vests, jogging pants and other long and short pants, and women’s sports bra with different strengths. The categories cover various scenes such as running, fitness, outdoor, commuting, tactics and women’s yoga, which have won favorable comments from many users. The X-BIONIC R&D team has carried out in-depth development for the products planned for autumn and winter in 2022. Most of the products have been developed and finalized, are being processed and produced, and continue to be updated.

SANFOPLUS’s own brand, combined with outdoor camping craze, develops and produces camping-themed fashion products, including various printed T-shirts, pants, trench coats and other products, which have won favorable comments from consumers and industry attention.

2) Agency brand

During the reporting period, the international brands represented by the company continued to maintain an upward trend. Under the Glamping (exquisite camping), mountain system and Gorpcore style trends, the Swedish classic brand Klattermusen (Pan mountain rat) continued to maintain a high-speed growth momentum, and continued to make efforts to promote brands and single products in Xiaohongshu, bilibili and Tik Tok, and cooperated with Xiaohongshu’s official platform to "explore the store by bloggers", which achieved both brand exposure and store realization. The sales of mountain rat’s first direct brand store, Zhejiang Hangzhou Building Store, jumped to the top three floors. The online self-operated Tmall Klattermusen Travel Mouse Store continued to exert its strength, constantly optimizing the interface and enhancing the store image, achieving a growth rate of 1,300%+ during the period of 618; German professional sports glove brand Reusch shined brilliantly in the 2022 Beijing Winter Olympics. In the alpine skiing competition, 90% of the winning athletes (including two alpine skiers in China) wore Reusch gloves and finished the competition, and the glove sales increased by 40% year-on-year. Professional outdoor backpacks MYSTERYRANCH, out shoes Boots DANNER, LASPORTIVA, Lizard, sports glasses Julbo and other companies continue to exert their strength in the outdoor and running market, and develop steadily.

3) Distribution and consignment of brands

During the reporting period, outdoor exquisite camping and ice and snow sports experienced explosive growth, and the company quickly adjusted its product structure. On the basis of the original outdoor camping equipment and ski products, Increase outdoor camping equipment brands such as BURTON, NORDISK, Barbecue Family, Gelong, MIFA, Guanya, Hengguang, Hermit Mountain Road, FOZZILS, Dilefu, and outdoor sports products brands such as MOJOSPARK, HAVAIANAS Havena, BALEGA, THERAGUN, Junlok, EMERSONGEARS and CRABGRAB, and the market feedback effect is good. In the second half of the year, the company will continue to enrich skiing and camping products.

2. Operating X-BIONIC black technology sports luxury brand

X-BIONIC is a luxury brand of black technology sports, "X" stands for technology, creativity, future and infinite possibilities, "BIONIC" stands for bionic technology, and X-BIONIC embodies the spirit of exploration, technology and passionate sports.

During the reporting period, the company continued to maintain all-round cooperative relations with international suppliers of high-quality materials such as GORE-TEX, Schoeller, Polartec, Pertex, Primaloft, Allied, Toray, Cordura, Carvico, etc. The company’s R&D team and the Swiss R&D team continued to communicate and cooperate, and developed and designed a series of products in spring and summer of 2022, with products in autumn and winter of 2021 superimposed, forming a full range, from inner layer to outer layer. At present, after market research, user communication, user feedback, team discussion and design adjustment, most products have been developed and finalized, are being processed and produced, and continue to be updated.

In May 2022, the company opened a ski shop in Chengdu Rongchuang Snow World, which mainly sells X-BIONIC brand products. With its technological advantages and cool decoration style, it gained a good reputation. In the second half of the year, the company will also open ski shops mainly selling X-BIONIC products in snow resorts such as Chongli, (), Tonghua Wanfeng and Xinjiang Jiangjun Mountain. As for the flagship store, the company hired an internationally renowned retail design company to complete the store image design, and has signed a contract with Beijing International Trade Mall, and plans to open the first brand flagship store of X-BIONIC in China from the end of September to the beginning of October.

In the 2022 Beijing Winter Olympics, China won a total of 15 medals, including 9 gold, 4 silver and 2 bronze, ranking third in the medal list. As a supplier of functional sportswear for the Winter Sports Management Center of the State General Administration of Sport, X-BIONIC has provided good equipment support for the athletes of 11 national teams in the Winter Olympics and Snow Sports. After the Winter Olympics, many sports and fashion media, such as X-bioni () Champion Sports Illustrated, filmed fashion blockbusters and short videos of many winter Olympic champions and outstanding athletes, such as Ren Ziwei, Xu Mengtao, Qi Guangpu, Gao Tingyu, Fan Kexin, Qu Chunyu and Ahenar, showing the highlights of the champions and the sports technology performance of X-BIONIC. The Winter Olympics ignited the ice and snow craze. X-BIONIC and Lamborghini Automobile held the "X-BIONIC Lamborghini Beijing Ice and Snow Tour" at the Yuyang International Ski Resort in Beijing. Many Lamborghini car owners and fashion celebrities participated in it to jointly create a high-end sports lifestyle. In the field of outdoor exploration, X-BIONIC sponsored many excellent climbers and expedition teams, including the second national Qinghai-Tibet expedition team, to provide them with equipment support. On June 6th, 2022, X-BIONIC sponsored climbers Gao Li, Ren Yong and Lu Ping successfully reached the summit of Yinfeng in Langemann at an altitude of 6,294 meters, becoming the first "China Team" to climb Yinfeng in Langemann.

In order to strengthen the middle and back-office management ability of X-BIONIC brand operation, the company cooperated strategically with Xiamen Nanxun Co., Ltd. to develop and deploy the online Nanxun ECRP system (omni-channel customer management system), open up the membership level, points and welfare system, launch the X-BIONIC member center, build a integral mall, maintain the after-sales platform, and integrate the recruitment entrance of member activities, so as to provide consumers with more professional outdoor extension services and meet the diversified needs of consumers.

X-BIONIC brand operation is the core business of the company in the next few years. The company will focus on the main resources and strive to build the X-BIONIC brand successfully as soon as possible.

3. Organize the group construction of outdoor activities.

(1) Sanfu event

During the reporting period, the Sanfu event prepared for the event in a positive state, and adjusted the work strategy in time according to the epidemic situation and industry trends, maximizing the use of online power to mobilize user activity and expand the influence of the event. At the beginning of the year, affected by the epidemic situation, Sanfu Games actively carried out the promotion and training of employees’ special skills, and organized related trainings such as first aid and volunteer management, aiming at improving employees’ professional abilities. At the same time, we actively carried out external liaison. Chongli 168 Super Cross-country Race reached a strategic partnership with Thailand’s Intanong Super Cross-country Race ByUTMB, which took an important step towards the internationalization of Chongli 168.

In the first half of 2022, in order to maximize the brand concept of the event, the official accounts of "Chongli 168 Super Cross-country Race" were newly set up, so as to better serve the contestants with more targeted push content. At the same time, the investment in the member service was increased, and the richness and convenience of small programs were fully utilized to provide various support services for the contestants. The Chongli 168 Super Cross-country Race held from July 22nd to 24th, with more than 7,000 participants, involved 9 tracks, 13 groups, 6 starting points and 2 finishing points. The total race lasted for 3 days, posing unprecedented challenges to the track, rescue, replenishment, operation, epidemic prevention and member service. At the same time, it continued to spread the advantages of the past channels such as live broadcast, online interaction and race record sharing. Affected by the epidemic in the first half of the year, the 23rd Sanshou Triathlon was postponed, and its preparations were suspended in the first half of the year. In the preparatory process, Sanfu event signed an agreement with China Triathlon Association, and this year’s event was upgraded to A+ level competition of China Railway Association, and the event was recognized as a specific theme competition of China Railway Association. The competition will become one of the main tasks of the Sanfu event in the second half of the year.

(2) Sanfu League Construction

Sanfu Youth League continued to expand the national territory of light luxury camping, deeply cultivated the enterprise team to expand the training field, delved into the physical fitness training of young people, and explored a new outdoor lifestyle.

During the reporting period, Sanfu Tuanjian actively organized the offline enterprise group building business, seized the outdoor fashion trend in the first half of the year, vigorously developed the inherent enterprise group building business, and at the same time, fully explored the outdoor C-end market, and made remarkable achievements in the continuous expansion of SanfoHood camping factory brand, and effectively linked with the parent-child outdoor park to create the "Sanfu Little Warrior" competition for children’s outdoor activities.

In the first half of 2022, the group construction business maintained sustained and healthy development. In March, the Goddess Festival theme group building products were built, and 13 group building activities were held in a single week. At the same time, seize the inter-provincial tourism window, quickly carry out high-end customized group building activities, and complete three outdoor group building activities such as "Hiking on Black Horse Camp Moganshan", "Yunqi Capital Sailing for hegemony" and "() Chongli Meadow Challenge", which have been widely praised by enterprises. Through the continuous upgrading and breakthrough of industrial resources, Sanfu Youth League has realized the leap-forward expansion of light luxury camping and small warrior project, and will also carry out new fields of large outdoor industry and explore a new outdoor lifestyle in the second half of the year.

4. Parent-child and adolescent comprehensive quality education project

(1) squirrel tribe parent-child outdoor amusement park

During the reporting period, the "Squirrel Tribe" overcame all kinds of difficulties brought by the external environment, adhered to its purpose, and strived to build an ecological family entertainment center integrating parent-child sports, popular science education, leisure and amusement, and ecological environment protection, and build a third space for children’s growth.

On the basis of the first outdoor amusement project, the "Squirrel Tribe" in Nanjing has completed the construction of the second water park and put it into operation. The operation effect is good and it is deeply loved by parents and children. Faced with people’s demand for short trips and their love for camping, the "Squirrel Tribe" followed the changes of market and consumption, and made use of its advantages of "field", "study" and "research" to launch "SanfoHood Squirrel Tribe Camp" and camping activities in Nanjing and Chengdu respectively. Unique activities have brought diversity and rich experience to the products of "Squirrel Tribe". In the first half of the year, the "squirrel tribe" received a total of 262,900 tourists under the haze of the epidemic.

"Squirrel Tribe" spreads and promotes on "two micro-shakes" in a popular way. The projects in Chengdu, Wuhan, Zhengzhou and Nanjing have registered their own official accounts on Tik Tok, WeChat and Weibo respectively, and regularly and irregularly launched project videos and tweets, making full use of online traffic, and making the "Squirrel Tribe" squeeze into the local hot-selling list through live broadcast and delivery.

With the effective implementation of the national epidemic prevention policy, tourism relief policies have been introduced one after another, and the company has full confidence in the market recovery in the second half of the year.

(2) Eagle Safety Education and Training

During the reporting period, Eagle Sports made full use of the epidemic intermission to complete the Guizhou provincial-level 1,000-person walking race, which was also the only large-scale outdoor event in Guizhou Province in the first half of the year. Completed the May Day camping tent festival, and began to build light luxury tent camps, and expanded the activities of light luxury tent group building and the government light luxury tent festival business; Relying on the main business of the safety sector, two large-scale government-sponsored drills were completed to ensure that the camp still maintained some just-needed businesses such as safety education and training under the epidemic situation. In the first half of the year, a total of 68 safety training activities were carried out, with 26,577 trainees.

Eagle Sports has reached a framework agreement with relevant departments in Nanjing to invest in Nanjing Eagle Sports, and completed the writing of the feasibility report of the project and the construction of the architectural renderings of the barracks area, laying the foundation for the next Nanjing project construction.

In the second half of the year, Eagle Sports will continue to enrich the safety product courses, expand more safety research travel business, and continue to undertake and implement the Yuntai Mountain Climbing Race (completed on July 30), Longli Rock Climbing Challenge, Light and Luxury Parent-child Tent Festival and other projects to maximize the target benefits.

(3)SanfoHood Wild Luxury Camp+Sanfu Little Warrior

During the reporting period, the brand of SanfoHood camping factory continued to expand and achieved impressive results. In the first half of the year, a total of 8 camps were landed and operated nationwide. With the mature systematic operation structure and previous camp operation experience, we successfully seized the holiday travel bonus period and handed over the perfect answer sheet that the average daily flow of a single camp exceeded 200 people. At the same time, it has reached a strategic cooperation agreement with two high-end homestays in Beijing, namely, Tile Factory Hotel and Mountain Lodge, to jointly build a wild luxury holiday tent camp, enrich the product formats around camping, and work together to promote the development of camping industry in China. Actively expand B-end customers with camp operation needs, and provide camp design and customized camping products such as tents and awnings. At present, it has provided related services to camp operation customers in many provinces and cities in China.

In the first half of 2022, Sanfu Little Warrior completed six events in Nanjing, Chengdu and Zhengzhou, and more than 1,000 families participated in a single event. It has won wide acclaim and certain influence in the local parent-child market. In the future, we will actively expand the creation of Little Warrior IP, further promote the diversification of children’s outdoor products and enrich the ecology of the whole industry.

Through the above business segments, the company provides consumers with all-round products and services, builds an outdoor ecological platform with business users as the core, links people with outdoor brands, people with outdoor products, people with outdoor sports, and people with outdoor education, so as to realize customer group transformation among different segments, thus building a complete outdoor industrial cycle.

(III) The position of the company

Since its establishment, the company has been deeply involved in the outdoor industry and committed to the upgrading of the outdoor sports industry. R&D and production of high-functional professional outdoor sporting goods, continuous expansion of the influence of competition activities, and creation of comprehensive quality education IP for parents and teenagers with social significance have formed a good reputation and brand reputation in the industry in line with the business philosophy of operating in good faith and ensuring after-sales. It is a leader in the development of outdoor industry in China and has been rated as "National Sports Industry Demonstration Unit" by the State Sports General Administration.

(A) retail business information analysis

1. Store operation

By the end of the reporting period, the company had opened 47 professional outdoor products chain stores in 18 cities, including Beijing, Shanghai, Nanjing, Hangzhou, Chengdu, Shenzhen, Shenyang, Changchun, Qingdao, Shijiazhuang, Suzhou, Wuxi, Wuhan, Chongqing, Dalian, Zhengzhou, Zhangjiakou and Jilin, with a total area of about 20,600 square meters.

(1) Distribution of stores at the end of the reporting period

(2) The situation of the top ten stores with sales revenue during the reporting period.

(3) Store business income

In the first half of 2022, the company’s store business income was 116,042,500 yuan, accounting for 48.98% of the company’s operating income.

2. Changes of stores during the reporting period

(1) Newly opened stores

(2) Close the store

3. Store efficiency information of comparable stores during the reporting period

Note:

(1) Comparable stores refer to stores with comparable sales data in 2021 and the first half of 2022.

(2) The above does not include the closing of stores in the first half of 2022.

(3) Floor efficiency refers to the sales per square meter of business area during the reporting period.

(II) Sales on the inside during the reporting period

During the reporting period, the transaction volume of the company’s third-party sales platform was 137,684,800 yuan. With the continuous development and increase of the third-party e-commerce platform, the company’s sales in official website have gradually been linked to the third-party sales platform.

(III) Procurement during the reporting period

1. Supply situation of the top five suppliers in each commodity category

2. Inventory management policy

In terms of inventory management, the company has applied ERP invoicing management and WMS warehousing management system, which can know the inventory situation in real time, and the data of goods warehousing, warehousing and distribution, sales outbound and end-of-season inventory can be reflected in real time, and the sales and inventory data of various stores in the country and the inventory structure of various categories can be obtained at any time from the system; The product department and the commercial control department of the company will formulate the safety inventory of each category, and arrange the replenishment quantity in time when the goods are out of stock, so as to ensure the continuous sales demand and avoid the stagnation of the goods.

3. Handling policies and impairment provision policies for unsalable and expired goods.

For unsalable goods, the company will take the form of returning to brand suppliers, big promotion in spring, summer or late autumn and winter, opening outlet stores and temporary special sales, e-commerce platform channels, micro-shopping malls and so on. For expired goods, the shelf life management regulations shall be strictly followed, and the principle of first-in-first-out shall be guaranteed. For temporary goods, measures such as returning to manufacturers and bundling promotion shall be taken, and expired goods shall be destroyed and included in the loss.

As for the impairment provision policy, it shall be measured at the lower of cost and net realizable value on the balance sheet date. If the inventory cost is higher than its net realizable value, provision for inventory depreciation shall be made and included in the current profit and loss. On the balance sheet date, if the factors influencing the previous write-down of inventory value have disappeared, the write-down amount will be restored, and it will be reversed within the amount of the original provision for inventory depreciation, and the reversed amount will be included in the current profit and loss.

(4) Warehousing and logistics during the reporting period.

The company’s central warehouse is located in Changping District, Beijing, close to Shahe Higher Education Park in the Sixth Ring Road, with convenient transportation. The warehouse covers an area of 5,000 square meters, and is used for rapid turnover and storage of a full range of goods sold by the company, including out shoes, clothes, bags and equipment. During the reporting period, the warehousing expenditure was 659,500 yuan, and the logistics expenditure was 2,984,400 yuan, of which the self-owned logistics expenditure accounted for 1.96% and the outsourcing logistics expenditure accounted for 98.04%.

(5) Own brand

During the reporting period, the company’s own brand operating income was 63,814,200 yuan, accounting for 29.11% of the company’s main business income. Among them, the operating income of X-BIONIC products was 52.2584 million yuan, and the sales increased by 118.32% year-on-year.

Note: The decimal difference of total operating income in the table is due to rounding.

II. Analysis of Core Competitiveness (I) The huge development space brought by the acquisition and operation of X-BIONIC, a luxury brand of black technology sports, has been widely recognized by many professional athletes in the world for its strong black technology attributes. "X" stands for technology, creativity, future and infinite possibilities, "BIONIC" stands for bionic technology, and X-BIONIC embodies the spirit of exploration, technology and passionate sports. After acquiring the ownership of "X-BIONIC" and "X-SOCKS" brands in China, the company absorbed and integrated its advanced technology, accepted the popularity and reputation of its international brands, combined with international and domestic R&D and production capacity adapted to the market, and closely cooperated with major international suppliers of high-quality raw materials, relying on the company’s accumulation in the outdoor sporting goods industry for many years, achieving brand development, which brought huge development space for the company’s production and operation. (II) Complete Outdoor Industry Operation Platform The company builds an outdoor ecological platform with operating users as the core, linking people with outdoor brands, outdoor products, outdoor sports and outdoor education by developing and selling professional high-quality outdoor sporting goods, operating X-BIONIC black technology sports luxury brands, organizing outdoor sports league construction, and designing, constructing and operating parent-child and adolescent comprehensive quality education projects. (III) Outdoor Multi-brand, All-category Product Structure Company, as one of the earlier enterprises engaged in outdoor industry, has been deeply involved in the industry since its establishment in 1997, and established a lasting and stable cooperative relationship with hundreds of outdoor brands at home and abroad, knowing the core advantages and applicable situations of different brands, different categories and different products, and forming in-depth insight and understanding of product characteristics, so as to provide professional and personalized product selection suggestions for different consumers in different scenarios and provide in-depth service to user groups. At present, the company has its own brands such as X-BIONIC, X-SOCKS, SANFOPLUS, ANEMAQEN, SANFO, KIDSANFO, etc., acting as an agent and distributing 300+ outdoor famous brands, with more than 8,000 SKUs. The product categories cover outdoor sports, daily business and leisure and other scenes. Some of the core brands are as follows: (4) Companies with strong R&D capabilities of their own brands have established many own brands such as ANEMAQEN, SANFO, KIDSANFO, SANFOPLUS, etc. by using more than 20 years of experience and in-depth understanding of products and customer groups, and have the ownership of IP in China, such as "X-BIONIC" and "X-SOCKS". The design R&D team consists of more than 40 professionals, including designers, typographers and material developers, focusing on the control of key links such as typography design, process optimization and production quality control.Focus on target market segmentation and diversified product design direction, constantly reform and innovate in fabric selection and functionality, and combine high-quality materials with advanced technology to empower sports and achieve a more comfortable, reassuring and cool brand experience. At present, the company has established in-depth cooperative business relations with international high-quality functional fabric companies including GORE-TEX, Schoeller, Polartec, Pertex, Primaloft, Allied, Toray, Cordura, Carvico, etc., which has laid a solid foundation for new product R&D, production and supply chain. Since the private brand products have been put into the market, they have gained a good market reputation, and the company’s core competitiveness and gross profit margin will be strongly guaranteed. (V) All-round distribution of sales channels The company has an independent team for expanding stores and a comprehensive evaluation system for opening stores. Combined with historical successful experience and business data, it evaluates and considers from various aspects such as region, consumption power, passenger flow, location, cost and return on investment, scientifically calculates and deduces the profit model, and selects excellent solutions to ensure the profitability of physical stores. Through offline channel coverage, online business development, group procurement promotion, event linkage and other means, we will comprehensively broaden sales channels and achieve online and offline coordinated development, which has strong industry influence in the professional outdoor field. (VI) Experience in organizing professional competitions and group building activities. The Sports Management Subsidiary has been focusing on the promotion and popularization of professional outdoor sports for many years.It has won the title of chinese mountaineering association Model Club and AAA outdoor sports club qualification for many years, and is a member of China Triathlon Association, Marathon Committee of China Athletics Association and International Cross-country Running Association. With the competition as the engine, the company is committed to leading Chinese people to develop a good outdoor sports lifestyle. At present, it has become a professional competition operation organization with large scale and strong technical strength in China, and its business ability is at the leading level in China from organization planning, route survey to guarantee implementation. The types of events cover daily training, entry-level events and long-distance super events, and there are many events with international brand influence such as Sanfu Triathlon and Chongli 168. The company has been fully recognized by members, contestants and outdoor sports enthusiasts in the event, and the members of the company have the characteristics of strong stability and high loyalty. The skill training subsidiary focuses on the in-depth development of enterprise group building business and occupies a leading position in the field of outdoor training for enterprises. After more than ten years of industry accumulation, a high-quality coach team composed of hundreds of professional senior coaches has been deposited, including many star coaches with national professional qualification certificates, more than ten years of experience and tens of thousands of training experiences. Established a deep cooperative relationship with many high-quality camp resources with unique outdoor entertainment attributes. After more than ten years of deep cultivation and business expansion, the company’s customer resources have covered more than 20 industries, including the Internet, technology and finance, including dozens of Fortune 500 companies, listed companies and emerging Internet technology companies. Quality customer resources,Long-term strategic cooperation, strong faculty and all-round enterprise services have enabled the company to win a stable market share and continue to drive business growth. (VII) Mature Operation and Management System of Quality Education Project for Parents and Teenagers Shanghai Xile Subsidiary is the main operator of "Squirrel Tribe". After years of exploration and practice in outdoor sports, entertainment and education, it has taken the lead in establishing standardized operation and management processes and curriculum research and development systems in the industry, and has a strong first-Mover advantage in product design, management concept, safety awareness and daily protection. "Squirrel Tribe" has its own brand IP image, and radiates clothing, picture books, courses and other related fields. By optimizing iterations, it enhances IP influence, systematically exports management service capabilities to the industry through joining, and enhances the radiation radius of IP regions. At present, the "Squirrel Tribe" has formed a good driving effect throughout the country. With the landing of projects with first-tier cities as the core, the brand awareness will be further enhanced. Eagle Sports Subsidiary owns the brand of "Eagle Safety Education", focusing on youth safety education, integrating diversified contents such as earthquake prevention and disaster reduction, self-care and self-rescue, popular science safety, youth safety education and training, etc. It can simulate various disaster sites to carry out various forms of skills training such as disaster prevention and mitigation, emergency rescue and emergency rescue, and enhance the self-help and self-care ability of young people in emergencies through experiential training. It has profound experience and mature operation mode in the youth safety quality education industry. Eagle sports investment and constructionGuizhou Yingji Outdoor Safety Base for Disaster Prevention and Mitigation has been awarded many honorary titles by Seismological Bureau of China, governments at all levels and superior units, such as National Popular Science Education Base for Earthquake Prevention and Mitigation, Publicity and Education Base for Disaster Prevention and Mitigation Safety in Guizhou Province, Publicity Base for Popular Science Education in Guizhou Province, and Training Base for Youth Self-care and Self-help in Guizhou Province. By continuously expanding the quality education program for teenagers, the company has become one of the representative enterprises in the field of outdoor unpowered sports, natural history exploration and safety education. (VIII) High-quality and stable membership group The company always adheres to the service tenet of "customer first", pays attention to the construction of customer information system, and uses CRM customer relationship management system to integrate online and offline multi-channel resources to carry out unified membership service and management. Actively cultivate new members, firmly maintain old members, increase value and optimize members’ rights and interests, and improve viscosity and repurchase rate; Establish accurate expansion of user portrait analysis needs; Provide timely and high-quality pre-sale, in-sale and after-sale services, pay attention to satisfaction feedback and follow up to enhance interaction; A loyal and stable membership base will help drive channel traffic and performance growth. (IX) The company with high industry popularity and reputation takes "encouraging and helping people to go outdoors, exercise healthily, and fully practicing the life concept of harmonious coexistence between man and nature" as its mission, and always adheres to the business philosophy of "honest management-ensuring after-sales" to provide consumers with multi-brand and full-range products. At the same time, to ensure the quality of service,The company has always adhered to the strategy of opening a store directly, and has established standardized management processes in product selection, storefront display, customer reception, professional explanation, inventory management, after-sales service, etc., which fundamentally ensures the unity and quality of foreign services. The company pays attention to establishing close cooperative relations with upstream and downstream enterprises and competent departments in the industrial chain, strictly fulfills commercial contracts, abides by business rules and business ethics, and has formed a good reputation and influence in the industry. In recent years, the company has won many awards, including National Sports Industry Demonstration Unit, Typical Enterprise of Ministry of Commerce, Zhongguancun High-tech Enterprise, Beijing AAA Credit Enterprise, Beijing Chengxin Creation Enterprise, Beijing Sports Industry Demonstration Unit, member units of Beijing Zhongguancun Enterprise Credit Promotion Association, Beijing Top 100 Private Enterprises with Social Responsibility, Beijing Top 100 Small and Medium Private Enterprises, Xicheng District Civilized Unit and Worker Pioneer, Zhongguancun Credit Cultivation Double Hundred Project "100 Most Influential Credit Enterprises" and so on. And ISO9001 quality management system certification, ISO14001 environmental management system certification, GB/T28001 occupational health and safety management system certification, etc.

Iii. Risks faced by the company and countermeasures (I) Risks that the X-BIONIC brand fails to meet expectations. Although the X-BIONIC brand has strong scientific and technological functional advantages, it takes a long time to establish brand awareness in the market as a new brand. Brand awareness also affects channel construction and sales performance. To fully operate the brand and test the company’s comprehensive ability, there is a risk that it will fail to meet expectations within a certain period of time. Countermeasures: Make clear the positioning of X-BIONIC black technology sports luxury brand, form a strong team from product research and development, brand marketing, channel construction and customer service, form operational capabilities, and ensure the stable and successful operation of X-BIONIC brand. (II) Risk of Force Majeure, such as repeated local epidemics and short-term stagnation of consumption. At present, domestic epidemics may face repeated situations. Repeated local epidemics may affect the sales of offline physical stores, the passenger flow of squirrel tribe parent-child outdoor paradise and Eagle safety education base, and the construction of outdoor games, and will also have an impact on the supply chain. Countermeasures: vigorously develop online business, seize new business opportunities such as camping, maintain close communication with international suppliers, send orders in advance to purchase and prepare emergency plans, control costs at the same time, adopt a more cautious attitude towards new project investment, and buffer the challenges brought by force majeure such as repeated epidemics to the greatest extent.